-

The Future Of Nano Technology

Categories

- Ai

- Alan Watts

- Anatomy

- Andropause

- Anti-Aging Medicine

- Arthritis

- Artificial General Intelligence

- Artificial Intelligence

- Artificial Super Intelligence

- Ataxia

- Autism

- Biochemistry

- BioEngineering

- Biotechnology

- Bitcoin

- Chemistry

- Cryonics

- Cryptocurrency

- David Sinclair

- Dementia

- Diet Science

- Diseases

- Eczema

- Elon Musk

- Futurism

- Gene Medicine

- Gene therapy

- Gene Therapy

- Genetic Medicine

- Genetic Therapy

- Global News Feed

- Healthy Lifestyle

- Healthy Living

- HGH Physicians

- Hormone Optimization

- Hormone Replacement Therapy

- Hormone Replacement Treatment

- Human Genetic Engineering

- Human Immortality

- Human Longevity

- Human Reproduction

- Hypogonadism

- Hypopituitarism

- Hypothyroidism

- Immortality

- Immortality Medicine

- Inflammation

- Injectable Growth Hormone

- Integrative Medicine

- Life Skills

- Longevity

- Longevity Medicine

- Low T

- Machine Learning

- Mars Colony

- Medical School

- Menopause

- multiple-sclerosis

- Nano Medicine

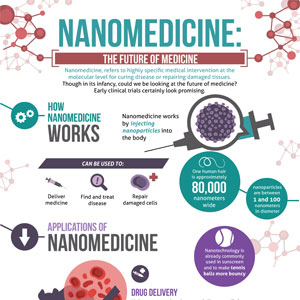

- Nanomedicine

- Nanotechnology

- Neurology

- Parkinson's disease

- Pharmacogenomics

- Protein Folding

- Psoriasis

- Quantum Computing

- Regenerative Medicine

- Resveratrol

- Sermorelin Physicians

- Singularity

- Spacex

- Stem Cell Therapy

- Stem Cells

- Stemcell Therapy

- Testosterone

- Testosterone Physicians

- Transhuman

- Transhumanism

- Transhumanist

- Uncategorized

- Veganism

- Vegetarianism

- Vitamin Research

- Wellness

-

Recent Posts

- Nanoscope Therapeutics: Gene Therapy Improves Visual Acuity in Patients with Retinitis Pigmentosa – 2 Minute Medicine

- College of Engineering Launches New Collaboratory for Biomedical and Bioengineering Innovation – UConn Today – University of Connecticut

- "The best decision I ever made:" Patel earns degree in biological engineering – University of Missouri College of Engineering

- Investigation of inherited noncoding genetic variation impacting the pharmacogenomics of childhood acute … – Nature.com

- Pharmacogenomics could improve medication safety and reduce waste – Healthcare IT News

Archives

Popular Key Word Searches

- centraltph

- bicarbonate and growth immunity ray peat

- vrcc neurology

- bibliotecapleyades/amrita-longevity-immortality

- cbr xmen anatomy

- Medical genetics wikipedia

- immortality medicine

- GrabPay

- Grab Pay Philippines

- GrabPay Vietnam

- GrabPay Philippines

- dr weil psoriasis

- what does recovered mean covid-19

- tony pantalleresco

- tony pantalleresco herbalist book

- herbsplusbeadworks

- herbsplusbeadworks website

- hailie vanderven

- princeton longevity center scam

- aetna genetic testing policy

- anatomy of hell

- biggie

- longevity claims

- augmentinforce tony pantalleresco

- tony pantalleresco website

| Search Immortality Topics: |

Category Archives: Biotechnology

biotechnology project by otter – Video

biotechnology project by otter

biology honors project.

By: Otterlax2011

See original here:

biotechnology project by otter - Video

Posted in Biotechnology

Comments Off on biotechnology project by otter – Video

Madison College and UW-Platteville Sign Biotechnology Articulation Agreement – Video

Madison College and UW-Platteville Sign Biotechnology Articulation Agreement

Madison College and UW-Platteville have signed an articulation agreement that gives biotechnology students the opportunity to earn a bachelor #39;s degree and a ...

By: MadisonCollegeVideo

Read this article:

Madison College and UW-Platteville Sign Biotechnology Articulation Agreement - Video

Posted in Biotechnology

Comments Off on Madison College and UW-Platteville Sign Biotechnology Articulation Agreement – Video

Who is Peter Milner | Optivia Biotechnology – Video

Who is Peter Milner | Optivia Biotechnology

Who are the Entrepreneurs - New Episode every Friday What does it take to be an entrepreneur? Get all the experts #39; tips and start planning your own business....

By: beactivebebusiness

Read the rest here:

Who is Peter Milner | Optivia Biotechnology - Video

Posted in Biotechnology

Comments Off on Who is Peter Milner | Optivia Biotechnology – Video

A Look At The Future Of Biotechnology In Beef Industry – Video

A Look At The Future Of Biotechnology In Beef Industry

By: BEEFmagTV

Read more:

A Look At The Future Of Biotechnology In Beef Industry - Video

Posted in Biotechnology

Comments Off on A Look At The Future Of Biotechnology In Beef Industry – Video

Metabolic engineering of Escherichia coli for high-specificity production of isoprenol and prenol as next generation of biofuels

Background:

The isopentenols, including isoprenol and prenol, are excellent alternative fuels. However, they are not compounds largely accumulated in natural organism. The need for the next generation of biofuels with better physical and chemical properties impels us to develop biosynthetic routes for the production of isoprenol and prenol from renewable sugar. In this study, we use the heterogenous mevalonate-dependent (MVA) isoprenoid pathway for the synthesis of isopentenyl pyrophosphate (IPP) and dimethylallyl pyrophosphate (DMAPP) intermediates, and then convert IPP and DMAPP to isoprenol and prenol, respectively.

Results:

A mevalonate titer of 1.7 g/L was obtained by constructing an efficient MVA upper pathway in engineered E. coli. Different phosphatases and pyrophosphatases were investigated for their abilities in hydrolyzing the IPP and DMAPP. Consequently, ADP-ribose pyrophosphatase was found to be an efficient IPP and DMAPP hydrolase. Moreover, ADP-ribose pyrophosphatase from Bacillus subtilis (BsNudF) exhibited a equivalent substrate specificity towards IPP and DMAPP, while ADP-ribose pyrophosphatase from E. coli (EcNudF) presented a high substrate preference for DMAPP. Without the expression of any phosphatases or pyrophosphatases, a background level of isopentenols was synthesized. When the endogenous pyrophosphatase genes (EcNudF and yggV) that were capable of enhancing the hydrolyzation of the IPP and DMAPP were knocked out, the background level of isopentenols was still obtained. Maybe the synthesized IPP and DMAPP were hydrolyzed by some unknown hydrolases of E. coli. Finally, 1.3 g/L single isoprenol was obtained by blocking the conversion of IPP to DMAPP and employing the BsNudF, and 0.2 g/L ~80% prenol was produced by employing the EcNudF. A maximal yield of 12% was achieved in both isoprenol and prenol producing strains.

Conclusions:

To the best of our knowledge, this is the first successful report on high-specificity production of isoprenol and prenol by microbial fermentation. Over 1.3 g/L isoprenol achieved in shake-flask experiments represents a quite encouraging titer of higher alcohols. In addition, the substrate specificities of ADP-ribose pyrophosphatases were determined and successfully applied for the high-specificity synthesis of isoprenol and prenol. Altogether, this work presents a promising strategy for high-specificity production of two excellent biofuels, isoprenol and prenol.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/57

Posted in Biotechnology

Comments Off on Metabolic engineering of Escherichia coli for high-specificity production of isoprenol and prenol as next generation of biofuels

Effects of steam pretreatment and co-production with ethanol on the energy efficiency and process economics of combined biogas, heat and electricity production from industrial hemp

Background:

The study presented here has used the commercial flow sheeting program Aspen PlusTM to evaluate techno-economic aspects of large-scale hemp-based processes for producing transportation fuels. The co-production of biogas, district heat and power from chopped and steam-pretreated hemp, and the co-production of ethanol, biogas, heat and power from steam-pretreated hemp were analysed. The analyses include assessments of heat demand, energy efficiency and process economics in terms of annual cash flows and minimum biogas and ethanol selling prices (MBSP and MESP).

Results:

Producing biogas, heat and power from chopped hemp has the highest overall energy efficiency, 84% of the theoretical maximum (based on lower heating values), providing that the maximum capacity of district heat is delivered. The combined production of ethanol, biogas, heat and power has the highest energy efficiency (49%) if district heat is not produced. Neither the inclusion of steam pretreatment nor co-production with ethanol has a large impact on the MBSP. Ethanol is more expensive to produce than biogas is, but this is compensated for by its higher market price. None of the scenarios examined are economically viable, since the MBSP (EUR 103--128 per MWh) is higher than the market price of biogas (EUR 67 per MWh). The largest contribution to the cost is the cost of feedstock. Decreasing the retention time in the biogas process for low solids streams by partly replacing continuous stirred tank reactors by high-rate bioreactors decreases the BMSP. Also, recycling part of the liquid from the effluent from anaerobic digestion decreases the MBSP. The production and prices of methane and ethanol influence the process economics more than the production and prices of electricity and district heat.

Conclusions:

To reduce the production cost of ethanol and biogas from biomass, the use of feedstocks that are cheaper than hemp, give higher output of ethanol and biogas, or combined production with higher value products are primarily suggested. Further, practical investigations on increased substrate concentration in biogas and ethanol production, recycling of the liquid in anaerobic digestion and separation of low solids flows into solid and a liquid fraction for improved reactor applications deserves further attention.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/56

Posted in Biotechnology

Comments Off on Effects of steam pretreatment and co-production with ethanol on the energy efficiency and process economics of combined biogas, heat and electricity production from industrial hemp