-

The Future Of Nano Technology

Categories

- Ai

- Alan Watts

- Anatomy

- Andropause

- Anti-Aging Medicine

- Arthritis

- Artificial General Intelligence

- Artificial Intelligence

- Artificial Super Intelligence

- Ataxia

- Autism

- Biochemistry

- BioEngineering

- Biotechnology

- Bitcoin

- Chemistry

- Cryonics

- Cryptocurrency

- David Sinclair

- Dementia

- Diet Science

- Diseases

- Eczema

- Elon Musk

- Futurism

- Gene Medicine

- Gene Therapy

- Gene therapy

- Genetic Medicine

- Genetic Therapy

- Global News Feed

- Healthy Lifestyle

- Healthy Living

- HGH Physicians

- Hormone Optimization

- Hormone Replacement Therapy

- Hormone Replacement Treatment

- Human Genetic Engineering

- Human Immortality

- Human Longevity

- Human Reproduction

- Hypogonadism

- Hypopituitarism

- Hypothyroidism

- Immortality

- Immortality Medicine

- Inflammation

- Injectable Growth Hormone

- Integrative Medicine

- Life Skills

- Longevity

- Longevity Medicine

- Low T

- Machine Learning

- Mars Colony

- Medical School

- Menopause

- multiple-sclerosis

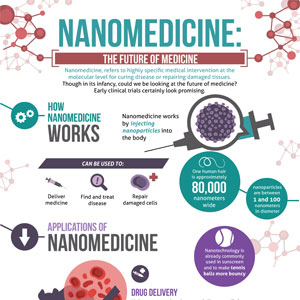

- Nano Medicine

- Nanomedicine

- Nanotechnology

- Neurology

- Parkinson's disease

- Pharmacogenomics

- Protein Folding

- Psoriasis

- Quantum Computing

- Regenerative Medicine

- Resveratrol

- Sermorelin Physicians

- Singularity

- Spacex

- Stem Cell Therapy

- Stem Cells

- Stemcell Therapy

- Testosterone

- Testosterone Physicians

- Transhuman

- Transhumanism

- Transhumanist

- Uncategorized

- Veganism

- Vegetarianism

- Vitamin Research

- Wellness

-

Recent Posts

- New Research Demonstrates the Importance of Genetic Testing for Many Cancers Not Currently Covered by Clinical … – PR Newswire

- UN treaty to look at indigenous medicine, genetic resources in patents | Loop St. Lucia – Loop News St. Lucia

- Kapow! Superpower launches preventative health and longevity platform – Longevity.Technology

- Healthy Longevity The Nutrition Source – Harvard University

- Electric Cars Are Twice as Likely to Hit Pedestrians, Researchers Find – Futurism

Archives

Popular Key Word Searches

- centraltph

- bicarbonate and growth immunity ray peat

- vrcc neurology

- bibliotecapleyades/amrita-longevity-immortality

- cbr xmen anatomy

- Medical genetics wikipedia

- immortality medicine

- GrabPay

- Grab Pay Philippines

- GrabPay Vietnam

- GrabPay Philippines

- dr weil psoriasis

- what does recovered mean covid-19

- tony pantalleresco

- tony pantalleresco herbalist book

- herbsplusbeadworks

- herbsplusbeadworks website

- hailie vanderven

- princeton longevity center scam

- aetna genetic testing policy

- anatomy of hell

- biggie

- longevity claims

- augmentinforce tony pantalleresco

- tony pantalleresco website

Search Results for: using nanotechnology coat objects

nanotechnology | Britannica.com

Nanotechnology, carbon nanotubeIllustration: Encyclopdia Britannica, Inc.; photographs:(microelectromechanical devices) Courtesy Sandia National Laboratories, SUMMiT Technologies; (quantum corral) courtesy IBM Research Center, unauthorized used not permitted; (red blood cells) Susumu Nishinaga/Science Source; (human hair) Manfred Kage/Peter Arnold, Inc.; (dust mite) Andrew Syred/Science Sourcethe manipulation and manufacture of materials and devices on the scale of atoms or small groups of atoms. The nanoscale is typically measured in nanometres, or billionths of a metre (nanos, the Greek word for dwarf, being the source of the prefix), and materials built at this scale often exhibit distinctive physical and chemical properties due to quantum mechanical effects. Although usable devices this small may be decades away (see microelectromechanical system), techniques for working at the nanoscale have become essential to electronic engineering, and nanoengineered materials have begun to appear in consumer products. For example, billions of microscopic nanowhiskers, each about 10 nanometres in length, have been molecularly hooked onto natural and synthetic fibres to impart stain resistance to clothing and other fabrics; zinc oxide nanocrystals have been used to create invisible sunscreens that block ultraviolet light; and silver nanocrystals have been embedded in bandages to kill bacteria and prevent infection.

Possibilities for the future are numerous. Nanotechnology may make it possible to manufacture lighter, stronger, and programmable materials that require less energy to produce than conventional materials, that produce less waste than with conventional manufacturing, and that promise greater fuel efficiency in land transportation, ships, aircraft, and space vehicles. Nanocoatings for both opaque and translucent surfaces may render them resistant to corrosion, scratches, and radiation. Nanoscale electronic, magnetic, and mechanical devices and systems with unprecedented levels of information processing may be fabricated, as may chemical, photochemical, and biological sensors for protection, health care, manufacturing, and the environment; new photoelectric materials that will enable the manufacture of cost-efficient solar-energy panels; and molecular-semiconductor hybrid devices that may become engines for the next revolution in the information age. The potential for improvements in health, safety, quality of life, and conservation of the environment are vast.

At the same time, significant challenges must be overcome for the benefits of nanotechnology to be realized. Scientists must learn how to manipulate and characterize individual atoms and small groups of atoms reliably. New and improved tools are needed to control the properties and structure of materials at the nanoscale; significant improvements in computer simulations of atomic and molecular structures are essential to the understanding of this realm. Next, new tools and approaches are needed for assembling atoms and molecules into nanoscale systems and for the further assembly of small systems into more-complex objects. Furthermore, nanotechnology products must provide not only improved performance but also lower cost. Finally, without integration of nanoscale objects with systems at the micro- and macroscale (that is, from millionths of a metre up to the millimetre scale), it will be very difficult to exploit many of the unique properties found at the nanoscale.

play_circle_outlinenanotechnology; pharmacology University of Melbourne, Victoria, Australia (A Britannica Publishing Partner)Nanotechnology is highly interdisciplinary, involving physics, chemistry, biology, materials science, and the full range of the engineering disciplines. The word nanotechnology is widely used as shorthand to refer to both the science and the technology of this emerging field. Narrowly defined, nanoscience concerns a basic understanding of physical, chemical, and biological properties on atomic and near-atomic scales. Nanotechnology, narrowly defined, employs controlled manipulation of these properties to create materials and functional systems with unique capabilities.

In contrast to recent engineering efforts, nature developed nanotechnologies over billions of years, employing enzymes and catalysts to organize with exquisite precision different kinds of atoms and molecules into complex microscopic structures that make life possible. These natural products are built with great efficiency and have impressive capabilities, such as the power to harvest solar energy, to convert minerals and water into living cells, to store and process massive amounts of data using large arrays of nerve cells, and to replicate perfectly billions of bits of information stored in molecules of deoxyribonucleic acid (DNA).

There are two principal reasons for qualitative differences in material behaviour at the nanoscale (traditionally defined as less than 100 nanometres). First, quantum mechanical effects come into play at very small dimensions and lead to new physics and chemistry. Second, a defining feature at the nanoscale is the very large surface-to-volume ratio of these structures. This means that no atom is very far from a surface or interface, and the behaviour of atoms at these higher-energy sites have a significant influence on the properties of the material. For example, the reactivity of a metal catalyst particle generally increases appreciably as its size is reducedmacroscopic gold is chemically inert, whereas at nanoscales gold becomes extremely reactive and catalytic and even melts at a lower temperature. Thus, at nanoscale dimensions material properties depend on and change with size, as well as composition and structure.

Using the processes of nanotechnology, basic industrial production may veer dramatically from the course followed by steel plants and chemical factories of the past. Raw materials will come from the atoms of abundant elementscarbon, hydrogen, and siliconand these will be manipulated into precise configurations to create nanostructured materials that exhibit exactly the right properties for each particular application. For example, carbon atoms can be bonded together in a number of different geometries to create variously a fibre, a tube, a molecular coating, or a wire, all with the superior strength-to-weight ratio of another carbon materialdiamond. Additionally, such material processing need not require smokestacks, power-hungry industrial machinery, or intensive human labour. Instead, it may be accomplished either by growing new structures through some combination of chemical catalysts and synthetic enzymes or by building them through new techniques based on patterning and self-assembly of nanoscale materials into useful predetermined designs. Nanotechnology ultimately may allow people to fabricate almost any type of material or product allowable under the laws of physics and chemistry. While such possibilities seem remote, even approaching natures virtuosity in energy-efficient fabrication would be revolutionary.

Even more revolutionary would be the fabrication of nanoscale machines and devices for incorporation into micro- and macroscale systems. Once again, nature has led the way with the fabrication of both linear and rotary molecular motors. These biological machines carry out such tasks as muscle contraction (in organisms ranging from clams to humans) and shuttling little packets of material around within cells while being powered by the recyclable, energy-efficient fuel adenosine triphosphate. Scientists are only beginning to develop the tools to fabricate functioning systems at such small scales, with most advances based on electronic or magnetic information processing and storage systems. The energy-efficient, reconfigurable, and self-repairing aspects of biological systems are just becoming understood.

The potential impact of nanotechnology processes, machines, and products is expected to be far-reaching, affecting nearly every conceivable information technology, energy source, agricultural product, medical device, pharmaceutical, and material used in manufacturing. Meanwhile, the dimensions of electronic circuits on semiconductors continue to shrink, with minimum feature sizes now reaching the nanorealm, under 100 nanometres. Likewise, magnetic memory materials, which form the basis of hard disk drives, have achieved dramatically greater memory density as a result of nanoscale structuring to exploit new magnetic effects at nanodimensions. These latter two areas represent another major trend, the evolution of critical elements of microtechnology into the realm of nanotechnology to enhance performance. They are immense markets driven by the rapid advance of information technology.

play_circle_outlineFeynman, Richard P.; quantum electrodynamics; nanotechnologyCourtesy of Northwestern University (A Britannica Publishing Partner)In a lecture in 1959 to the American Physical Society, Theres Plenty of Room at the Bottom, American Nobelist Richard P. Feynman presented his audience with a vision of what could be done with extreme miniaturization. He began his lecture by noting that the Lords Prayer had been written on the head of a pin and asked,

Why cannot we write the entire 24 volumes of the Encyclopdia Britannica on the head of a pin? Lets see what would be involved. The head of a pin is a sixteenth of an inch across. If you magnify it by 25,000 diameters, the area of the head of the pin is then equal to the area of all the pages of the Encyclopdia Britannica. Therefore, all it is necessary to do is to reduce in size all the writing in the Encyclopdia by 25,000 times. Is that possible? The resolving power of the eye is about 1/120 of an inchthat is roughly the diameter of one of the little dots on the fine half-tone reproductions in the Encyclopdia. This, when you demagnify it by 25,000 times, is still 80 angstroms in diameter32 atoms across, in an ordinary metal. In other words, one of those dots still would contain in its area 1,000 atoms. So, each dot can easily be adjusted in size as required by the photoengraving, and there is no question that there is enough room on the head of a pin to put all of the Encyclopdia Britannica.

Feynman was intrigued by biology and pointed out that

cells are very tiny, but they are very active; they manufacture various substances; they walk around; they wiggle; and they do all kinds of marvelous thingsall on a very small scale. Also, they store information. Consider the possibility that we too can make a thing very small which does what we wantthat we can manufacture an object that maneuvers at that level!

He also considered using big tools to make smaller tools that could make yet smaller tools, eventually obtaining nanoscale tools for directly manipulating atoms and molecules. In considering what all this might mean, Feynman declared,

I can hardly doubt that when we have some control of the arrangement of things on a small scale we will get an enormously greater range of possible properties that substances can have, and of different things that we can do.

Perhaps the biggest barrier to following these prophetic thoughts was simply the immediate lack of tools to manipulate and visualize matter at such a small scale. The availability of tools has always been an enabling aspect of the advance of all science and technology, and some of the key tools for nanotechnology are discussed in the next section, Pioneers.

Starting with a 1981 paper in the Proceedings of the National Academy of Sciences and following with two popular books, Engines of Creation (1986) and Nanosystems (1992), American scientist K. Eric Drexler became one of the foremost advocates of nanotechnology. In fact, Drexler was the first person anywhere to receive a Ph.D. in molecular nanotechnology (from the Massachusetts Institute of Technology). In his written works he takes a molecular view of the world and envisions molecular machines doing much of the work of the future. For example, he refers to assemblers, which will manipulate individual atoms to manufacture structures, and replicators, which will be able to make multiple copies of themselves in order to save time dealing with the billions of atoms needed to make objects of useful size. In an article for Encyclopdia Britannicas 1990 Yearbook of Science and the Future, Drexler wrote:

Cells and tissues in the human body are built and maintained by molecular machinery, but sometimes that machinery proves inadequate: viruses multiply, cancer cells spread, or systems age and deteriorate. As one might expect, new molecular machines and computers of subcellular size could support the bodys own mechanisms. Devices containing nanocomputers interfaced to molecular sensors and effectors could serve as an augmented immune system, searching out and destroying viruses and cancer cells. Similar devices programmed as repair machines could enter living cells to edit out viral DNA sequences and repair molecular damage. Such machines would bring surgical control to the molecular level, opening broad new horizons in medicine.

Drexlers futurist visions have stimulated much thought, but the assembler approach has failed to account for the strong influence of atomic and molecular forces (i.e., the chemistry) at such dimensions. The controversy surrounding these popularizations, and the potential dangers of entities such as intelligent replicators (however remote), have stimulated debate over the ethical and societal implications of nanotechnology.

A number of key technological milestones have been achieved by working pioneers. Molecular beam epitaxy, invented by Alfred Cho and John Arthur at Bell Labs in 1968 and developed in the 1970s, enabled the controlled deposition of single atomic layers. This tool provided for nanostructuring in one dimension as atomic layers were grown one upon the next. It subsequently became important in the area of compound semiconductor device fabrication. For example, sandwiching one-nanometre-thick layers of nonmagnetic-sensor materials between magnetic layers in computer disk drives resulted in large increases in storage capacity, and a similar use of nanostructuring resulted in more energy-efficient semiconductor lasers for use in compact disc players.

In 1981 Gerd Binnig and Heinrich Rohrer developed the scanning tunneling microscope at IBMs laboratories in Switzerland. This tool provided a revolutionary advance by enabling scientists to image the position of individual atoms on surfaces. It earned Binnig and Rohrer a Nobel Prize in 1986 and spawned a wide variety of scanning probe tools for nanoscale observations.

The observation of new carbon structures marked another important milestone in the advance of nanotechnology, with Nobel Prizes for the discoverers. In 1985 Robert F. Curl, Jr., Harold W. Kroto, and Richard E. Smalley discovered the first fullerene, the third known form of pure carbon (after diamond and graphite). They named their discovery buckminsterfullerene (buckyball) for its resemblance to the geodesic domes promoted by the American architect R. Buckminster Fuller. Technically called C60 for the 60 carbon atoms that form their hollow spherical structure, buckyballs resemble a football one nanometre in diameter (see figure). In 1991 Sumio Iijima of NEC Corporation in Japan discovered carbon nanotubes, in which the carbon ringlike structures are extended from spheres into long tubes of varying diameter. Taken together, these new structures surprised and excited the imaginations of scientists about the possibilities of forming well-defined nanostructures with unexpected new properties.

The scanning tunneling microscope not only allowed for the imaging of atoms by scanning a sharp probe tip over a surface, but it also allowed atoms to be pushed around on the surface. With a slight bias voltage applied to the probe tip, certain atoms could be made to adhere to the tip used for imaging and then to be released from it. Thus, in 1990 Donald Eigler spelled out the letters of his companys logo, IBM, by moving 35 xenon atoms into place on a nickel surface. This demonstration caught the publics attention because it showed the precision of the emerging nanoscale tools.

At nanoscale dimensions the properties of materials no longer depend solely on composition and structure in the usual sense. Nanomaterials display new phenomena associated with quantized effects and with the preponderance of surfaces and interfaces.

Quantized effects arise in the nanometre regime because the overall dimensions of objects are comparable to the characteristic wavelength for fundamental excitations in materials. For example, electron wave functions (see also de Broglie wave) in semiconductors are typically on the order of 10 to 100 nanometres. Such excitations include the wavelength of electrons, photons, phonons, and magnons, to name a few. These excitations carry the quanta of energy through materials and thus determine the dynamics of their propagation and transformation from one form to another. When the size of structures is comparable to the quanta themselves, it influences how these excitations move through and interact in the material. Small structures may limit flow, create wave interference effects, and otherwise bring into play quantum mechanical selection rules not apparent at larger dimensions.

Quantum mechanical properties for confinement of electrons in one dimension have long been exploited in solid-state electronics. Semiconductor devices are grown with thin layers of differing composition so that electrons (or holes in the case of missing electron charges) can be confined in specific regions of the structure (known as quantum wells). Thin layers with larger energy bandgaps can serve as barriers that restrict the flow of charges to certain conditions under which they can tunnel through these barriersthe basis of resonant tunneling diodes. Superlattices are periodic structures of repeating wells that set up a new set of selection rules which affect the conditions for charges to flow through the structure. Superlattices have been exploited in cascade lasers to achieve far infrared wavelengths. Modern telecommunications is based on semiconductor lasers that exploit the unique properties of quantum wells to achieve specific wavelengths and high efficiency.

The propagation of photons is altered dramatically when the size and periodicity of the transient structure approach the wavelength of visible light (400 to 800 nanometres). When photons propagate through a periodically varying dielectric constantfor example, semiconductor posts surrounded by airquantum mechanical rules define and limit the propagation of the photons depending on their energy (wavelength). This new behaviour is analogous to the quantum mechanical rules that define the motion of electrons through crystals, giving bandgaps for semiconductors. In one dimension, compound semiconductor superlattices can be grown epitaxially with the alternating layers having different dielectric constants, thus providing highly reflective mirrors for specific wavelengths as determined by the repeat distance of layers in the superlattice. These structures are used to provide built-in mirrors for vertical-cavity surface-emitting lasers, which are used in communications applications. In two and three dimensions, periodic structures known as photonic crystals offer additional control over photon propagation.

Photonic crystals are being explored in a variety of materials and periodicities, such as two-dimensional hexagonal arrays of posts fabricated in compound semiconductors or stacked loglike arrays of silicon bars in three dimensions. The dimensions of these structures depend on the wavelength of light being propagated and are typically in the range of a few hundred nanometres for wavelengths in the visible and near infrared. Photonic crystal properties based on nanostructured materials offer the possibility of confining, steering, and separating light by wavelength on unprecedented small scales and of creating new devices such as lasers that require very low currents to initiate lasing (called near-thresholdless lasers). These structures are being extensively investigated as the tools for nanostructuring materials are steadily advancing. Researchers are particularly interested in the infrared wavelengths, where dimensional control is not as stringent as at the shorter visible wavelengths and where optical communications and chemical sensing provide motivation for potential new applications.

Nanoscale materials also have size-dependent magnetic behaviour, mechanical properties, and chemical reactivity. At very small sizes (a few nanometres), magnetic nanoclusters have a single magnetic domain, and the strongly coupled magnetic spins on each atom combine to produce a particle with a single giant spin. For example, the giant spin of a ferromagnetic iron particle rotates freely at room temperature for diameters below about 16 nanometres, an effect termed superparamagnetism. Mechanical properties of nanostructured materials can reach exceptional strengths. As a specific example, the introduction of two-nanometre aluminum oxide precipitates into thin films of pure nickel results in yield strengths increasing from 0.15 to 5 gigapascals, which is more than twice that for a hard bearing steel. Another example of exceptional mechanical properties at the nanoscale is the carbon nanotube, which exhibits great strength and stiffness along its longitudinal axis.

The preponderance of surfaces is a major reason for the change in behaviour of materials at the nanoscale. Since up to half of all the atoms in nanoparticles are surface atoms, properties such as electrical transport are no longer determined by solid-state bulk phenomena. Likewise, the atoms in nanostructures have a higher average energy than atoms in larger structures, because of the large proportion of surface atoms. For example, catalytic materials have a greater chemical activity per atom of exposed surface as the catalyst is reduced in size at the nanoscale. Defects and impurities may be attracted to surfaces and interfaces, and interactions between particles at these small dimensions can depend on the structure and nature of chemical bonding at the surface. Molecular monolayers may be used to change or control surface properties and to mediate the interaction between nanoparticles.

Surfaces and their interactions with molecular structures are basic to all biology. The intersection of nanotechnology and biotechnology offers the possibility of achieving new functions and properties with nanostructured surfaces. In this surface- and interface-dominated regime, biology does an exquisite job of selectively controlling functions through a combination of structure and chemical forces. The transcription of information stored in genes and the selectivity of biochemical reactions based on chemical recognition of complex molecules are examples where interfaces play the key role in establishing nanoscale behaviour. Atomic forces and chemical bonds dominate at these dimensions, while macroscopic effectssuch as convection, turbulence, and momentum (inertial forces)are of little consequence.

As discussed in the section Properties at the nanoscale, material propertieselectrical, optical, magnetic, mechanical, and chemicaldepend on their exact dimensions. This opens the way for development of new and improved materials through manipulation of their nanostructure. Hierarchical assemblies of nanoscale-engineered materials into larger structures, or their incorporation into devices, provide the basis for tailoring radically new materials and machines.

Natures assemblies point the way to improving structural materials. The often-cited abalone seashell provides a beautiful example of how the combination of a hard, brittle inorganic material with nanoscale structuring and a soft, tough organic material can produce a strong, durable nanocompositebasically, these nanocomposites are made of calcium carbonate bricks held together by a glycoprotein glue. New engineered materials are emergingsuch as polymer-clay nanocompositesthat are not only strong and tough but also lightweight and easier to recycle than conventional reinforced plastics. Such improvements in structural materials are particularly important for the transportation industry, where reduced weight directly translates into improved fuel economy. Other improvements can increase safety or decrease the impact on the environment of fabrication and recycling. Further advances, such as truly smart materials that signal their impending failure or are even able to self-repair flaws, may be possible with composites of the future.

Sensors are central to almost all modern control systems. For example, multiple sensors are used in automobiles for such diverse tasks as engine management, emission control, security, safety, comfort, vehicle monitoring, and diagnostics. While such traditional applications for physical sensing generally rely on microscale sensing devices, the advent of nanoscale materials and structures has led to new electronic, photonic, and magnetic nanosensors, sometimes known as smart dust. Because of their small size, nanosensors exhibit unprecedented speed and sensitivity, extending in some cases down to the detection of single molecules. For example, nanowires made of carbon nanotubes, silicon, or other semiconductor materials exhibit exceptional sensitivity to chemical species or biological agents. Electrical current through nanowires can be altered by having molecules attached to their surface that locally perturb their electronic band structure. By means of nanowire surfaces coated with sensor molecules that selectively attach particular species, charge-induced changes in current can be used to detect the presence of those species. This same strategy is adopted for many classes of sensing systems. New types of sensors with ultrahigh sensitivity and specificity will have many applications; for example, sensors that can detect cancerous tumours when they consist of only a few cells would be a very significant advance.

Nanomaterials also make excellent filters for trapping heavy metals and other pollutants from industrial wastewater. One of the greatest potential impacts of nanotechnology on the lives of the majority of people on Earth will be in the area of economical water desalination and purification. Nanomaterials will very likely find important use in fuel cells, bioconversion for energy, bioprocessing of food products, waste remediation, and pollution-control systems.

A recent concern regarding nanoparticles is whether their small sizes and novel properties may pose significant health or environmental risks. In general, ultrafine particlessuch as the carbon in photocopier toners or in soot produced by combustion engines and factorieshave adverse respiratory and cardiovascular effects on people and animals. Studies are under way to determine if specific nanoscale particles pose higher risks that may require special regulatory restrictions. Of particular concern are potential carcinogenic risks from inhaled particles and the possibility for very small nanoparticles to cross the blood-brain barrier to unknown effect. Nanomaterials currently receiving attention from health officials include carbon nanotubes, buckyballs, and cadmium selenide quantum dots. Studies of the absorption through the skin of titanium oxide nanoparticles (used in sunscreens) are also planned. More far-ranging studies of the toxicity, transport, and overall fate of nanoparticles in ecosystems and the environment have not yet been undertaken. Some early animal studies, involving the introduction of very high levels of nanoparticles which resulted in the rapid death of many of the subjects, are quite controversial.

Nanotechnology promises to impact medical treatment in multiple ways. First, advances in nanoscale particle design and fabrication provide new options for drug delivery and drug therapies. More than half of the new drugs developed each year are not water-soluble, which makes their delivery difficult. In the form of nanosized particles, however, these drugs are more readily transported to their destination, and they can be delivered in the conventional form of pills.

More important, nanotechnology may enable drugs to be delivered to precisely the right location in the body and to release drug doses on a predetermined schedule for optimal treatment. The general approach is to attach the drug to a nanosized carrier that will release the medicine in the body over an extended period of time or when specifically triggered to do so. In addition, the surfaces of these nanoscale carriers may be treated to seek out and become localized at a disease sitefor example, attaching to cancerous tumours. One type of molecule of special interest for these applications is an organic dendrimer. A dendrimer is a special class of polymeric molecule that weaves in and out from a hollow central region. These spherical fuzz balls are about the size of a typical protein but cannot unfold like proteins. Interest in dendrimers derives from the ability to tailor their cavity sizes and chemical properties to hold different therapeutic agents. Researchers hope to design different dendrimers that can swell and release their drug on exposure to specifically recognized molecules that indicate a disease target. This same general approach to nanoparticle-directed drug delivery is being explored for other types of nanoparticles as well.

Another approach involves gold-coated nanoshells whose size can be adjusted to absorb light energy at different wavelengths. In particular, infrared light will pass through several centimetres of body tissue, allowing a delicate and precise heating of such capsules in order to release the therapeutic substance within. Furthermore, antibodies may be attached to the outer gold surface of the shells to cause them to bind specifically to certain tumour cells, thereby reducing the damage to surrounding healthy cells.

A second area of intense study in nanomedicine is that of developing new diagnostic tools. Motivation for this work ranges from fundamental biomedical research at the level of single genes or cells to point-of-care applications for health delivery services. With advances in molecular biology, much diagnostic work now focuses on detecting specific biological signatures. These analyses are referred to as bioassays. Examples include studies to determine which genes are active in response to a particular disease or drug therapy. A general approach involves attaching fluorescing dye molecules to the target biomolecules in order to reveal their concentration.

Another approach to bioassays uses semiconductor nanoparticles, such as cadmium selenide, which emit light of a specific wavelength depending on their size. Different-size particles can be tagged to different receptors so that a wider variety of distinct colour tags are available than can be distinguished for dye molecules. The degradation in fluorescence with repeated excitation for dyes is avoided. Furthermore, various-size particles can be encapsulated in latex beads and their resulting wavelengths read like a bar code. This approach, while still in the exploratory stage, would allow for an enormous number of distinct labels for bioassays.

Another nanotechnology variation on bioassays is to attach one half of the single-stranded complementary DNA segment for the genetic sequence to be detected to one set of gold particles and the other half to a second set of gold particles. When the material of interest is present in a solution, the two attachments cause the gold balls to agglomerate, providing a large change in optical properties that can be seen in the colour of the solution. If both halves of the sequence do not match, no agglomeration will occur and no change will be observed.

Approaches that do not involve optical detection techniques are also being explored with nanoparticles. For example, magnetic nanoparticles can be attached to antibodies that in turn recognize and attach to specific biomolecules. The magnetic particles then act as tags and handlebars through which magnetic fields can be used for mixing, extracting, or identifying the attached biomolecules within microlitre- or nanolitre-sized samples. For example, magnetic nanoparticles stay magnetized as a single domain for a significant period, which enables them to be aligned and detected in a magnetic field. In particular, attached antibodymagnetic-nanoparticle combinations rotate slowly and give a distinctive magnetic signal. In contrast, magnetically tagged antibodies that are not attached to the biological material being detected rotate more rapidly and so do not give the same distinctive signal.

play_circle_outlinematerials science; wrinkle formation Massachusetts Institute of Technology (A Britannica Publishing Partner)Microfluidic systems, or labs-on-chips, have been developed for biochemical assays of minuscule samples. Typically cramming numerous electronic and mechanical components into a portable unit no larger than a credit card, they are especially useful for conducting rapid analysis in the field. While these microfluidic systems primarily operate at the microscale (that is, millionths of a metre), nanotechnology has contributed new concepts and will likely play an increasing role in the future. For example, separation of DNA is sensitive to entropic effects, such as the entropy required to unfold DNA of a given length. A new approach to separating DNA could take advantage of its passage through a nanoscale array of posts or channels such that DNA molecules of different lengths would uncoil at different rates.

Other researchers have focused on detecting signal changes as nanometre-wide DNA strands are threaded through a nanoscale pore. Early studies used pores punched in membranes by viruses; artificially fabricated nanopores are also being tested. By applying an electric potential across the membrane in a liquid cell to pull the DNA through, changes in ion current can be measured as different repeating base units of the molecule pass through the pores. Nanotechnology-enabled advances in the entire area of bioassays will clearly impact health care in many ways, from early detection, rapid clinical analysis, and home monitoring to new understanding of molecular biology and genetic-based treatments for fighting disease.

Another biomedical application of nanotechnology involves assistive devices for people who have lost or lack certain natural capabilities. For example, researchers hope to design retinal implants for vision-impaired individuals. The concept is to implant chips with photodetector arrays to transmit signals from the retina to the brain via the optic nerve. Meaningful spatial information, even if only at a rudimentary level, would be of great assistance to the blind. Such research illustrates the tremendous challenge of designing hybrid systems that work at the interface between inorganic devices and biological systems.

Closely related research involves implanting nanoscale neural probes in brain tissue to activate and control motor functions. This requires effective and stable wiring of many electrodes to neurons. It is exciting because of the possibility of recovery of control for motor-impaired individuals. Studies employing neural stimulation of damaged spinal cords by electrical signals have demonstrated the return of some locomotion. Researchers are also seeking ways to assist in the regeneration and healing of bone, skin, and cartilagefor example, developing synthetic biocompatible or biodegradable structures with nanosized voids that would serve as templates for regenerating specific tissue while delivering chemicals to assist in the repair process. At a more sophisticated level, researchers hope to someday build nanoscale or microscale machines that can repair, assist, or replace more-complex organs.

Semiconductor experts agree that the ongoing shrinkage in conventional electronic devices will inevitably reach fundamental limits due to quantum effects such as tunneling, in which electrons jump out of their prescribed circuit path and create atomic-scale interference between devices. At that point, radical new approaches to data storage and information processing will be required for further advances. For example, radically new systems have been imagined that are based on quantum computing or biomolecular computing.

The use of molecules for electronic devices was suggested by Mark Ratner of Northwestern University and Avi Aviram of IBM as early as the 1970s, but proper nanotechnology tools did not become available until the turn of the 21st century. Wiring up molecules some half a nanometre wide and a few nanometres long remains a major challenge, and an understanding of electrical transport through single molecules is only beginning to emerge. A number of groups have been able to demonstrate molecular switches, for example, that could conceivably be used in computer memory or logic arrays. Current areas of research include mechanisms to guide the selection of molecules, architectures for assembling molecules into nanoscale gates, and three-terminal molecules for transistor-like behaviour. More-radical approaches include DNA computing, where single-stranded DNA on a silicon chip would encode all possible variable values and complementary strand interactions would be used for a parallel processing approach to finding solutions. An area related to molecular electronics is that of organic thin-film transistors and light emitters, which promise new applications such as video displays that can be rolled out like wallpaper and flexible electronic newspapers.

Carbon nanotubes have remarkable electronic, mechanical, and chemical properties. Depending on their specific diameter and the bonding arrangement of their carbon atoms, nanotubes exhibit either metallic or semiconducting behaviour. Electrical conduction within a perfect nanotube is ballistic (negligible scattering), with low thermal dissipation. As a result, a wire made from a nanotube, or a nanowire, can carry much more current than an ordinary metal wire of comparable size. At 1.4 nanometres in diameter, nanotubes are about a hundred times smaller than the gate width of silicon semiconductor devices. In addition to nanowires for conduction, transistors, diodes, and simple logic circuits have been demonstrated by combining metallic and semiconductor carbon nanotubes. Similarly, silicon nanowires have been used to build experimental devices, such as field-effect transistors, bipolar transistors, inverters, light-emitting diodes, sensors, and even simple memory. A major challenge for nanowire circuits, as for molecular electronics, is connecting and integrating these devices into a workable high-density architecture. Ideally, the structure would be grown and assembled in place. Crossbar architectures that combine the function of wires and devices are of particular interest.

At nanoscale dimensions the energy required to add one additional electron to a small island (isolated physical region)for example, through a tunneling barrierbecomes significant. This change in energy provides the basis for devising single-electron transistors. At low temperatures, where thermal fluctuations are small, various single-electron-device nanostructures are readily achievable, and extensive research has been carried out for structures with confined electron flow. However, room-temperature applications will require that sizes be reduced significantly, to the one-nanometre range, to achieve stable operation. For large-scale application with millions of devices, as found in current integrated circuits, the need for structures with very uniform size to maintain uniform device characteristics presents a significant challenge. Also, in this and many new nanodevices being explored, the lack of gain is a serious drawback limiting implementation in large-scale electronic circuits.

Spintronics refers to electronic devices that perform logic operations based on not just the electrical charge of carriers but also their spin. For example, information could be transported or stored through the spin-up or spin-down states of electrons. This is a new area of research, and issues include the injection of spin-polarized carriers, their transport, and their detection. The role of nanoscale structure and electronic properties of the ferromagnetic-semiconductor interface on the spin injection process, the growth of new ferromagnetic semiconductors with nanoscale control, and the possible use of nanostructured features to manipulate spin are all of interest.

Current approaches to information storage and retrieval include high-density, high-speed, solid-state electronic memories, as well as slower (but generally more spacious) magnetic and optical discs (see computer memory). As the minimum feature size for electronic processing approaches 100 nanometres, nanotechnology provides ways to decrease further the bit size of the stored information, thus increasing density and reducing interconnection distances for obtaining still-higher speeds. For example, the basis of the current generation of magnetic disks is the giant magnetoresistance effect. A magnetic read/write head stores bits of information by setting the direction of the magnetic field in nanometre-thick metallic layers that alternate between ferromagnetic and nonferromagnetic. Differences in spin-dependent scattering of electrons at the interface layers lead to resistance differences that can be read by the magnetic head. Mechanical properties, particularly tribology (friction and wear of moving surfaces), also play an important role in magnetic hard disk drives, since magnetic heads float only about 10 nanometres above spinning magnetic disks.

Another approach to information storage that is dependent on designing nanometre-thick magnetic layers is under commercial development. Known as magnetic random access memory (MRAM), a line of electrically switchable magnetic material is separated from a permanently magnetized layer by a nanoscale nonmagnetic interlayer. A resistance change that depends on the relative alignment of the fields is read electrically from a large array of wires through cross lines. MRAM will require a relatively small evolution from conventional semiconductor manufacturing, and it has the added benefit of producing nonvolatile memory (no power or batteries are needed to maintain stored memory states).

Still at an exploratory stage, studies of electrical conduction through molecules have generated interest in their possible use as memory. While still very speculative, molecular and nanowire approaches to memory are intriguing because of the small volume in which the bits of memory are stored and the effectiveness with which biological systems store large amounts of information.

Nanoscale structuring of optical devices, such as vertical-cavity surface-emitting lasers (VCSELs), quantum dot lasers, and photonic crystal materials, is leading to additional advances in communications technology.

VCSELs have nanoscale layers of compound semiconductors epitaxially grown into their structurealternating dielectric layers as mirrors and quantum wells. Quantum wells allow the charge carriers to be confined in well-defined regions and provide the energy conversion into light at desired wavelengths. They are placed in the lasers cavity to confine carriers at the nodes of a standing wave and to tailor the band structure for more efficient radiative recombination. One-dimensional nanotechnology techniques involving precise growth of very thin epitaxial semiconductor layers were developed during the 1990s. Such nanostructuring has enhanced the efficiency of VCSELs and reduced the current required for lasing to start (called the threshold current). Because of improving performance and their compatibility with planar manufacturing technology, VCSELs are fast becoming a preferred laser source in a variety of communications applications.

More recently, the introduction of quantum dots (regions so small that they can be given a single electric charge) into semiconductor lasers has been investigated and found to give additional benefitsboth further reductions in threshold current and narrower line widths. Quantum dots further confine the optical emission modes within a very narrow spectrum and give the lowest threshold current densities for lasing achieved to date in VCSELs. The quantum dots are introduced into the laser during the growth of strained layers, by a process called Stransky-Krastanov growth. They arise because of the lattice mismatch stress and surface tension of the growing film. Improvements in ways to control precisely the resulting quantum dots to a more uniform single size are still being sought.

Photonic crystals provide a new means to control the steering and manipulation of photons based on periodic dielectric lattices with repeat dimensions on the order of the wavelength of light. These materials can have very exotic properties, such as not allowing light within certain wavelengths to be propagated in a material based on the particular periodic structure. Photonic lattices can act as perfect wavelength-selective mirrors to reflect back incident light from all orientations. They provide the basis for optical switching, steering, and wavelength separation on unprecedented small scales. The periodic structures required for these artificial crystals can be configured as both two- and three-dimensional lattices. Optical sources, switches, and routers are being considered, with two-dimensional planar geometries receiving the most attention, because of their greater ease of fabrication.

Another potentially important communications application for nanotechnology is microelectromechanical systems (MEMS), devices sized at the micrometre level (millionths of a metre). MEMS are currently poised to have a major impact on communications via optical switching. In the future, electromechanical devices may shrink to nanodimensions to take advantage of the higher frequencies of mechanical vibration at smaller masses. The natural (resonant) frequency of vibration for small mechanical beams increases as their size decreases, so that little power is needed to drive them as oscillators. Their efficiency is rated by a quality factor, known as Q, which is a ratio of the energy stored per cycle versus the energy dissipated per cycle. The higher the Q, the more precise the absolute frequency of an oscillator. The Q is very high for micro- and nanoscale mechanical oscillators, and these devices can reach very high frequencies (up to microwave frequencies), making them potential low-power replacements for electronic-based oscillators and filters.

Mechanical oscillators have been made from silicon at dimensions of 10 100 nanometres, where more than 10 percent of the atoms are less than one atomic distance from the surface. While highly homogeneous materials can be made at these dimensionsfor example, single-crystal silicon barssurfaces play an increasing role at nanoscales, and energy losses increase, presumably because of surface defects and molecular species absorbed on surfaces.

It is possible to envision even higher frequencies, in what might be viewed as the ultimate in nanomechanical systems, by moving from nanomachined structures to molecular systems. As an example, multiwalled carbon nanotubes are being explored for their mechanical properties. When the ends of the outer nanotube are removed, the inner tube may be pulled partway out from the outer tube where van der Waals forces between the two tubes will supply a restoring force. The inner tube can thus oscillate, sliding back and forth inside the outer tube. The resonant frequency of oscillation for such structures is predicted to be above one gigahertz (one billion cycles per second). It is unknown whether connecting such systems to the macro world and protecting them from surface effects will ever be practical.

Corrections? Updates? Help us improve this article! Contact our editors with your Feedback.

See the original post:

nanotechnology | Britannica.com

Posted in Nanotechnology

Comments Off on nanotechnology | Britannica.com

Nanotechnology – ScienceDaily

Nanotechnology refers broadly to a field of applied science and technology whose unifying theme is the control of matter on the molecular level in scales smaller than 1 micrometre, normally 1 to 100 nanometers, and the fabrication of devices within that size range.

It is a highly multidisciplinary field, drawing from fields such as applied physics, materials science, colloidal science, device physics, supramolecular chemistry, and even mechanical and electrical engineering.

Much speculation exists as to what new science and technology may result from these lines of research.

Nanotechnology can be seen as an extension of existing sciences into the nanoscale, or as a recasting of existing sciences using a newer, more modern term.

Two main approaches are used in nanotechnology.

In the "bottom-up" approach, materials and devices are built from molecular components which assemble themselves chemically by principles of molecular recognition.

In the "top-down" approach, nano-objects are constructed from larger entities without atomic-level control.

The impetus for nanotechnology comes from a renewed interest in colloidal science, coupled with a new generation of analytical tools such as the atomic force microscope (AFM), and the scanning tunneling microscope (STM).

Combined with refined processes such as electron beam lithography and molecular beam epitaxy, these instruments allow the deliberate manipulation of nanostructures, and led to the observation of novel phenomena.

Examples of nanotechnology in modern use are the manufacture of polymers based on molecular structure, and the design of computer chip layouts based on surface science.

Despite the great promise of numerous nanotechnologies such as quantum dots and nanotubes, real commercial applications have mainly used the advantages of colloidal nanoparticles in bulk form, such as suntan lotion, cosmetics, protective coatings, and stain resistant clothing.

Modern synthetic chemistry has reached the point where it is possible to prepare small molecules to almost any structure.

These methods are used today to produce a wide variety of useful chemicals such as pharmaceuticals or commercial polymers.

This ability raises the question of extending this kind of control to the next-larger level, seeking methods to assemble these single molecules into supramolecular assemblies consisting of many molecules arranged in a well defined manner.

These approaches utilize the concepts of molecular self-assembly and/or supramolecular chemistry to automatically arrange themselves into some useful conformation through a bottom-up approach.

The concept of molecular recognition is especially important: molecules can be designed so that a specific conformation or arrangement is favored due to non-covalent intermolecular forces.

The Watson-Crick basepairing rules are a direct result of this, as is the specificity of an enzyme being targeted to a single substrate, or the specific folding of the protein itself.

Thus, two or more components can be designed to be complementary and mutually attractive so that they make a more complex and useful whole.

Follow this link:

Nanotechnology - ScienceDaily

Posted in Nanotechnology

Comments Off on Nanotechnology – ScienceDaily

What is Nanotechnology? – ZL Wang’s Homepage

What is Nanotechnology?

by Zhong L. Wang

In the history of industrial engineering, technology characterized by length only occurred in microelectronics, but now we have nanotechnology. How small is one nanometer? The typical width of a human hair is 50 micrometers. One nanometer is 50,000th of a hair width.

Nanotechnology is the construction and use of functional structures designed from atomic or molecular scale with at least one characteristic dimension measured in nanometers. Their size allows them to exhibit novel and significantly improved physical, chemical, and biological properties, phenomena, and processes because of their size. When characteristic structural features are intermediate between isolated atoms and bulk materials in the range of about one to 100 nanometers, the objects often display physical attributes substantially different from those displayed by either atoms or bulk materials.

Phenomena at the nanometer scale are likely to be a completely new world. Properties of matter at nanoscale may not be as predictable as those observed at larger scales. Important changes in behavior are caused not only by continuous modification of characteristics with diminishing size, but also by the emergence of totally new phenomena such as quantum confinement, a typical example of which is that the color of light emitting from semiconductor nanoparticles depends on their sizes. Designed and controlled fabrication and integration of nanomaterials and nanodevices is likely to be revolutionary for science and technology.

Nanotechnology can provide unprecedented understanding about materials and devices and is likely to impact many fields. By using structure at nanoscale as a tunable physical variable, we can greatly expand the range of performance of existing chemicals and materials. Alignment of linear molecules in an ordered array on a substrate surface (self-assembled monolayers) can function as a new generation of chemical and biological sensors. Switching devices and functional units at nanoscale can improve computer storage and operation capacity by a factor of a million. Entirely new biological sensors facilitate early diagnostics and disease prevention of cancers. Nanostructured ceramics and metals have greatly improved mechanical properties, both in ductility and strength.

From the fundamental units of materials, all natural materials and systems establish their foundation at nanoscale; controlling matter at atomic or molecular levels means tailoring the fundamental properties, phenomena, and processes exactly at the scale where the basic properties are initiated. Nanotechnology could impact the production of virtually every human-made object from automobiles and electronics to advanced diagnostics, surgery, advanced medicines, and tissue and bone replacements. To build electronic devices using atom-by-atom engineering, for example, we have to understand the interaction among atoms and molecules, how to manipulate them, how to keep them stable, how to communicate signals among them, and how to face them with the real world. This goal requires new knowledge, new tools, and new approaches.

back to top

Much more than miniaturization

To many people, nanotechnology may be understood as a process of ultra-miniaturization. Philosophically, changes in quantity result in changes in quality. Shrinkage in device size may lead to a change in operation principle due to quantum effect, which is the physics that governs the motion and interaction of electrons in atoms. In fact, the trend in product miniaturization will require new process measurement and control systems that can span across millimeter-, micrometer-, and nanometer-sized scales while accounting for the associated physics that govern the device and environment interaction at each specific size scale.

To consider the interactions among atoms in the nanometer scale, we need to introduce quantum mechanics and each atom has to be treated as a unit. To face the atoms with the real world in the millionmeter scale, we need to consider the collective properties of millions and millions of atoms, so that the matter is considered to be a continuous medium, and we use classical mechanics. The bridging of the two length scales requires new standardized architecture definitions that support multiple physics-based models and new computational representations that allow seamless transition and traversing through these various models.

back to top

Manufacturing nanomaterials

Nanomanufacturing technologies that will support tailor-made products having functionally critical nanometer-scale dimensions are produced using massively parallel systems or self-assembly. The current research mainly focuses on nanoscience for discovering new materials, novel phenomena, new characterization tools, and fabricating nanodevices. The future impact of nanotechnology to human civilization is manufacturing. The small feature size in nanotechnology that limits application of wellestablished optical lithography and manipulation techniques causes industrial nanomanufacturing to remain a serious challenge to our technological advances.

Synthesis of nanomaterials is one of the most active fields in nanotechnology. There are numerous methods for synthesizing nanomaterials of various characteristics. An essential challenge in synthesis is controlling the structures at a high yield for industrial applications. Techniques are needed for atomic and molecular control of material building blocks, which can be assembled, used, and tailored for fabricating devices of multifunctionality in many applications.

The oxide nanobelt discovered in my laboratory is an example. Ultra-long nanobelts have been successfully synthesized for a wide range of oxides by simply evaporating the desired commercial metal oxide powders at high temperatures. These materials are semiconductors with important applications in sensors and transducers. The as-synthesized oxide nanobelts are pure and structurally uniform; they have a rectangular-like cross-section. The semiconducting oxide nanobelts could be doped with different elements and be used for fabricating nanometer-sized sensors based on the characteristics of individual nanobelts, which could be potentially useful for in-situ, real-time, and remote detection of molecules, cancel cells, or proteins based on electronic signal. The nanobelts could also be used for fabrication of nanoscale electronic and optoelectronic devices because they are semiconductors.

back to top

Characterizing the performance and properties of nanostructures

Property characterization of nanomaterials is challenging because of the difficulties in manipulating structures of such small size. New tools and approaches must be developed to meet new challenges. Due to the high size and structure selectivity of nanomaterials, their physical properties could be quite diverse, depending on their atomic-scale structure, size, and chemistry. A typical example is the carbon nanotube, which is made of concentrical cylindrical graphite sheets with a diameter range from one to 400 nanometers and length of a few micrometers. Characterizing the mechanical properties of individual nanotubes, for example, is a challenge to many testing and measuring techniques because of the following constraints. First, the size (diameter and length) is rather small, prohibiting the application of wellestablished testing techniques. Tensile and creep testing require that the size of the sample be sufficiently large to be clamped rigidly by the sample holder without sliding. This is impossible for one-dimensional nanomaterials using conventional means. Second, the small size of the nanostructure makes their manipulation rather difficult, and specialized techniques are needed for picking up and installing individual nanostructures. Therefore, new methods and methodologies must be developed to quantify the properties of individual nanostructures.

In-situ transmission electron microscopy technique, or TEM, has been developed for measuring the modulus of individual carbon nanotubes. We have to see the object while its properties are being measured, thus, a microscope is required. To carry out the property measurement of a nanotube, a specimen holder for a TEM was built for applying a voltage across a nanotube and its counter electrode. To measure the bending modulus of a carbon nanotube, an oscillating voltage is applied on the nanotube that can tune the frequency of the applied voltage. By changing the frequency of the applied voltage onto the nanotube, mechanical resonance can be induced in carbon nanotubes at specific frequencies from which the bending modulus can be derived. This type of technique works well for small objects.

back to top

Large-scale manipulation and self-assembly

Manipulation of nanostructures relies on scanning probe microscopy. Using a fine tip, atoms, nanoparticles, or nanowires can be manipulated for a variety of applications. This type of approach is outstanding for scientific research. For manufacturing, an array of scanning tips, if synchronized, may be used for achieving atom-by-atom engineering. But the building rate is rather slow. If a device has a feature size of five nanometers and a scanning tip can move atoms 10 atoms per second, it will take about six months to build 1012 devices on an eight-inch wafer.

The ultimate solution is self-assembly. Like many biological systems, self-assembly is the most fundamental process for forming a functional and living structure. The genetic codes and sequence built in a biosystem guide and control the self-assembling process. Self-assembly is the organization and pattern formed naturally by the fundamental building blocks such as molecules and cells. Designed and controlled self-assembly is a possible solution for future manufacturing needs.

Size- and shape-selected nanocrystals behave like molecular matter that can be used as fundamental building blocks for constructing nanocrystal-assembled superlattices. Self-assembled arrays involve selforganization into monolayers, thin films, and superlattices of size-selected nanocrystals encapsulated in a protective compact organic coating. Nanocrystals are the hard cores that preserve the ordering at the atomic scale; the organic molecules adsorbed on their surfaces serve as the interparticle molecular bonds and as protection for the particles in order to avoid direct core contact with a consequence of coalescing. The interparticle interaction can be changed via control over the length of the molecular chains, resulting in tunable electronic, optical, and transport properties.

back to top

Large-scale parallel device fabrication and system integration

System integration involves at least an integration of numerous functional materials and components for achieving a complex, preprogrammed action. This involves patterned materials growth on a designed substrate; large-scale, parallel integration of nanowires, nanoparticles, and functional groups; interconnection among the components; and defect-tolerated path design following neuron networks. A wide range of novel approaches has been developed for fabrication of single nanodevices. Nanomanufacturing requires a simultaneous, parallel fabrication of a large amount of nanodevices under precisely controlled conditions and repeatability. This remains a major challenge to the development of nanotechnology, especially for nanoelectronics. A possible solution is to integrate patterns produced by lithographic technique with self-assembly process. Self-assembly of single-walled carbon nanotubes is one example.

By functionalizing the substrate produced by lithographic technique so that individual carbon nanotubes selectively recognize the locations for self-assemble on the substrate following specific patterns, mass producing carbon nanotube-based circuit structures is possible. To achieve the process, the substrate was coated with patterns of organic molecules using techniques such as dip-pen nanolithography and microcontact stamping. Two surface regions have been produced: one patterned with polar chemical groups, and the second coated with non-polar groups. A suspension of single-walled carbon nanotubes solution was added, and the nanotubes were attracted to the polar regions and self-assembled to form predesigned structures. Millions of individual nanotubes have been patterned on stamp-generated microscale patterns, covering areas of about one square centimeter on gold.

back to top

Integrating nanometer-to-millimeter manufacturing technologies

Over the next decade, major industrial and scientific trends that emerged during the 1990s will influence not only how manufacturing will be done, but also what is manufactured. The size of many manufactured goods continues to decrease, resulting in ultra-miniature electronic devices and new hybrid technologies. For example, micro-electromechanical system, or MEMS, devices integrate physical, chemical, and even biological processes in micro- and millimeter-scale technology packages. MEMS devices are used in many sectors: information technology, medicine and health, aerospace, automotive, environment, and energy, to name a few.

The future relies on the integration of nanotechnology with existing technology. The challenge remains in integrating nanotechnology with microelectronics-based technology. The nanometer-scale components have to be connected with micrometer- and millimeter-scale components to communicate with the real world. This requires an integration of not only the technologies covering nanometer-to-millimeter multilength scales, but also the physics and chemistry covering the entire length scale. We are facing the merging of quantum mechanics and classical mechanics. Any ultra small components have to be connected with the real world. The goal should be on how to use nanotechnology to make microtechnology more efficient, multifunctional, and intelligent as well as faster, smaller, and achieving the impossible. Nanotechnology comes to life if we can achieve the integration of nanoscale building blocks with lithographically produced structures through self-assembly and genetically engineered growth.

back to top

Building nanomanufacturing standards

Nanomanufacturing needs the measurements and standards required to achieve effective and validated nanoscale product and process performance. This challenge is mainly in the following three directions:

Atomic-scale manufacturing: Develop and assemble the technologies required to fabricate standards that are atomically precise. This will include work directed at solving artifact integrity, precision placement, dimensional metrology, and manufacturing issues.

Molecular-scale manipulation and assembly: Identify and address the fundamental measurement, control, and standards issues related to manipulation and assembly of microscale or nanoscale devices using optical, physical, or chemical methods. This entails building the manipulation technology and using it to understand and address the measurement issues that arise when assembling devices at the microscale or nanoscale level.

Micro-to-millimeter-scale manufacturing technologies: Develop the technologies required to position, manipulate, assemble, and manufacture across nanometer-to-millimeter multilength scales.

back to top

Not just an engineering process

Traditionally, manufacturing is attributed to an engineering field. For nanomanufacturing, we must go beyond engineering. Once we approach the atomic-scale precision and control, fundamental physics and chemistry have to be applied. The nanoscale manufacturing is multidisciplinary -- involving but not limited to mechanics, electrical engineering, physics, chemistry, biology, and biomedical engineering. The future view of nanomanufacturing is the integration of engineering, science and biology. This complex task requires not only innovative research and development themes, but also a new education system for training future scientists and engineers.

back to top

See the article here:

What is Nanotechnology? - ZL Wang's Homepage

Posted in Nanotechnology

Comments Off on What is Nanotechnology? – ZL Wang’s Homepage

Silver Saver – Nanotechnology Keeps the Shine on Silver – Video

Silver Saver - Nanotechnology Keeps the Shine on Silver

Scientists from the Department of Materials Science and Engineering at the A. James Clark School of Engineering, University of Maryland, have teamed up with conservators from the Walters Art Museum in Baltimore, Md., to develop and test a new, high-tech way to protect silver art objects and artifacts, using coatings that are mere nanometers thick. The technique, called atomic layer deposition (ALD), will be used to create metal oxide films which, when applied to an artifact, are both transparent and optimized to reduce the rate of silver corrosion. The project is funded by the NSF #39;s SCIART grant program, which supports research in the field of cultural heritage science through the funding of collaborations among conservation experts in museums and scientists in academia. In April 2011 the National Science Foundation #39;s Science Nation web site, which highlights scientific discoveries for the public, debuted this video segment about the project called "Silver Saver," narrated by former CNN chief technology and environment correspondent Miles O #39;Brien.

By: livingselfsufficient

More here:

Silver Saver - Nanotechnology Keeps the Shine on Silver - Video

Posted in Nanotechnology

Comments Off on Silver Saver – Nanotechnology Keeps the Shine on Silver – Video

Emerging technologies – The News International

The rapid emergence of new technologies is transforming the world around us in almost magical ways. They range from strange new materials that make objects invisible to the naked eye when they are coated by those materials, to new species of plants and animals that can be created in the lab through a process of gene editing.

Devices have been developed that restore partial eyesight to the blind through images that can be transferred through the nervous system of the tongue to the brain. Anti-ageing compounds are being developed that slow down the process of ageing. It is thought that children being born today will have average lives of 120 years plus. Graphene has been developed which is 200 times stronger than steel and it is finding many applications.

Artificial intelligence is developing at a very rapid pace and finding its way in a myriad applications, ranging from city traffic management to drug discovery, from stock exchange appraisals to unravelling health and environmental issues. There is particular interest in the applications of artificial intelligence in areas like neural networking.

Some of these new technologies are finding their way into modern warfare. Swarms of intelligent drones that can interact together and attack enemy tanks in a highly organized and orchestrated manner are changing the dynamics of war and making the tank and the foot soldier progressively redundant. The Turkish Bayraktar TB2 drone, a combat drone with a wingspan of 12 meters and an armament of four laser-guided bombs, along with others supplied from the West have caused havoc to Russian tanks and other heavy ground weaponry. Small portable switchblade drones are also being successfully employed in Ukraine. These are comfortably transported in a tube from which they can be launched directly. Once launched, their wings snap out and the propulsion systems are activated.

Another rapidly emerging field is that of nanotechnology. Nanotechnology emerged serendipitously when it was discovered that remarkable changes of properties in materials occur when their sizes are reduced to between one nanometer (nm) and 100 nm. A nanometer is a billionth of a meter about the same proportion to a meter, as a marble is to the earth. For instance, if we pulverize gold particles and bring them to the nano-meter size, then the colour of gold changes to blue-green, red or purple, depending on the particle size

Nanotechnology applications range across all science fields such as biomedical, chemical, mechanics, electronics, computer sciences and material science. Nanoscale sensors and devices are providing cost-effective continuous monitoring of the structural integrity and performance of bridges, tunnels etc. They are also being employed to support an enhanced transportation infrastructure to help drivers maintain lane position, avoid collisions, adjust travel routes to avoid congestion.

Nanotechnology is also finding a multitude of applications in water purification, medicine, cosmetics, electronics, new materials and many other fields. In the field of nano-electronics alone, the market size is estimated to be around $4 trillion and is growing rapidly. Similarly bullet-proof jackets have been developed based on bullet proof paper made from nano-cellulose these jackets are light, absorbent and bullet proof! The global nanotechnology market size is estimated to be at about $1.80 billion and it is projected to reach $33.63 billion by 2030, registering a CAGR of 36.4 percent from 2021 to 2030.

Another exciting area of rapid development is that of energy. New and more efficient solar cells are being developed. Special paints have been developed with built-in solar cells so that they can produce electricity when sunlight falls on them. Advances on new more efficient batteries to drive electric cars are another area of hot research.

These and other amazing technologies are rapidly transforming our world, and the businesses that can produce and make use of them are flourishing. It is interesting that computer systems based on biological models was the fastest-growing technology among the new and emerging technologies with 67 percent growth in terms of new patents filed between 2016 and 2020. Google, Microsoft and Intel are leaders in the area. Major increases are also being seen in the new patents filed in the fields of machine learning, quantum computing, autonomous technology and 3D printing.

Excellent beginnings in some of these fields have been made in Pakistan with the establishment of the Pak Austrian University of Applied Science and Engineering (Pak Austrian Fachhochschule) in Haripur, Hazara and a similar university is now under construction in Sialkot. Several centers for Artificial Intelligence have been established including the excellent National Center for Artificial Intelligence in NUST, Islamabad, as well as in NED Engineering University, UET Lahore and other universities.

The Sino-Pak Center for Artificial Intelligence has also begun operations in the Pak Austrian University in Haripur in collaboration with top universities in China and Austria. Pakistans first National Center for Nanotechnology has been established at the International Center for Chemical and Biological Sciences at Karachi University.