-

The Future Of Nano Technology

Categories

- Ai

- Alan Watts

- Anatomy

- Andropause

- Anti-Aging Medicine

- Arthritis

- Artificial General Intelligence

- Artificial Intelligence

- Artificial Super Intelligence

- Ataxia

- Autism

- Biochemistry

- BioEngineering

- Biotechnology

- Bitcoin

- Chemistry

- Cryonics

- Cryptocurrency

- David Sinclair

- Dementia

- Diet Science

- Diseases

- Eczema

- Elon Musk

- Futurism

- Gene Medicine

- Gene therapy

- Gene Therapy

- Genetic Medicine

- Genetic Therapy

- Global News Feed

- Healthy Lifestyle

- Healthy Living

- HGH Physicians

- Hormone Optimization

- Hormone Replacement Therapy

- Hormone Replacement Treatment

- Human Genetic Engineering

- Human Immortality

- Human Longevity

- Human Reproduction

- Hypogonadism

- Hypopituitarism

- Hypothyroidism

- Immortality

- Immortality Medicine

- Inflammation

- Injectable Growth Hormone

- Integrative Medicine

- Life Skills

- Longevity

- Longevity Medicine

- Low T

- Machine Learning

- Mars Colony

- Medical School

- Menopause

- multiple-sclerosis

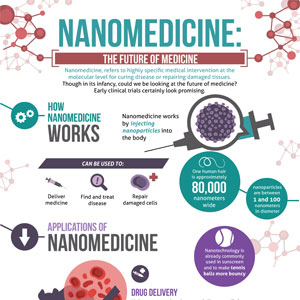

- Nano Medicine

- Nanomedicine

- Nanotechnology

- Neurology

- Parkinson's disease

- Pharmacogenomics

- Protein Folding

- Psoriasis

- Quantum Computing

- Regenerative Medicine

- Resveratrol

- Sermorelin Physicians

- Singularity

- Spacex

- Stem Cell Therapy

- Stem Cells

- Stemcell Therapy

- Testosterone

- Testosterone Physicians

- Transhuman

- Transhumanism

- Transhumanist

- Uncategorized

- Veganism

- Vegetarianism

- Vitamin Research

- Wellness

-

Recent Posts

- Nanoscope Therapeutics: Gene Therapy Improves Visual Acuity in Patients with Retinitis Pigmentosa – 2 Minute Medicine

- College of Engineering Launches New Collaboratory for Biomedical and Bioengineering Innovation – UConn Today – University of Connecticut

- "The best decision I ever made:" Patel earns degree in biological engineering – University of Missouri College of Engineering

- Investigation of inherited noncoding genetic variation impacting the pharmacogenomics of childhood acute … – Nature.com

- Pharmacogenomics could improve medication safety and reduce waste – Healthcare IT News

Archives

Popular Key Word Searches

- centraltph

- bicarbonate and growth immunity ray peat

- vrcc neurology

- bibliotecapleyades/amrita-longevity-immortality

- cbr xmen anatomy

- Medical genetics wikipedia

- immortality medicine

- GrabPay

- Grab Pay Philippines

- GrabPay Vietnam

- GrabPay Philippines

- dr weil psoriasis

- what does recovered mean covid-19

- tony pantalleresco

- tony pantalleresco herbalist book

- herbsplusbeadworks

- herbsplusbeadworks website

- hailie vanderven

- princeton longevity center scam

- aetna genetic testing policy

- anatomy of hell

- biggie

- longevity claims

- augmentinforce tony pantalleresco

- tony pantalleresco website

| Search Immortality Topics: |

Category Archives: Biotechnology

New vaccine therapy to treat the deadly chemo-resistant ovarian cancer

A better hope for thousands of women suffering from the ‘often resistant to chemotherapy’ ovarian cancer at its advanced stage. A new cancer vaccine therapy is on its way to launch expanding treatment options to such women. Thanks to the Cancer Treatment Centers of America. The vaccine is developed by AVAX Technologies, Inc. Dr. Edgar Staren, Chief Medical Officer of Cancer Treatment Centers of America said, Cancer Treatment Centers of America’s number one priority is to help our patients win the battle against cancer. This vaccine therapy represents a promising new chapter in the fight against this devastating disease and brings hope to women everywhere. Interestingly, this treatment method creates a patient-specific vaccine, using the patient’s own tumor tissues. The method also combines chemotherapy delivered directly into the abdominal cavity along with it. Dr. Staren said, To win the fight against cancer, it is absolutely vital we do everything we can to make innovative new treatments like this available to patients as soon as possible. It’s inconceivable that treatments like these – that give hope to patients – are often left on the laboratory bench, while cancer patients are told there is nothing more that can be done for them.

Posted in Biotechnology

Comments Off on New vaccine therapy to treat the deadly chemo-resistant ovarian cancer

Eat your slice of beef without the contamination grief

Consumers of canned beef and swine can now stay assured of the quality of the food and relish the taste without any fear of contamination courtesy ‘IdentiGEN’. IdentiGEN has developed TraceBack, the first-ever commercial DNA-fingerprinting technology for meat. The process starts at the farm or slaughterhouse, where animals are given are tested for pathogens. After receiving a clean bill of health, a worker takes a sample of the cow’s blood, meat or hair, analyzes it for genetic identifiers known as single-nucleotide polymorphisms, and stores the information in a central database. Before packaging is done at supermarket, the butchers take another DNA sample and checks it with the database to be sure of a 100% healthy packaged meat. And if there is trace of any errant pathogen found, the source can be traced back within hours thus making it possible for food-safety officials to nail down the source of the outbreak. According to Ronan Loftus, IdentiGEN’s director of business development: Each product has its own inherent label. It’s like nature’s bar code. Once this system is in place, you can pull a package of meat off the shelves and access its entire history. And the consumers have to pay a negligible premium to get 100% healthy meat.

Posted in Biotechnology

Comments Off on Eat your slice of beef without the contamination grief

Tracking dynamics of plant biomass composting by changes in substrate structure, microbial community, and enzyme activity

Background:

Understanding the dynamics of the microbial communities that, along with their secreted enzymes, are involved in the natural process of biomass composting may hold the key to breaking the major bottleneck in biomass-to-biofuels conversion technology, which is the still-costly deconstruction of polymeric biomass carbohydrates to fermentable sugars. However, the complexity of both the structure of plant biomass and its counterpart microbial degradation communities makes it difficult to investigate the composting process.

Results:

In this study, a composter was set up with a mix of yellow poplar (Liriodendron tulipifera) wood-chips and mown lawn grass clippings (85:15 in dry-weight) and used as a model system. The microbial rDNA abundance data obtained from analyzing weekly-withdrawn composted samples suggested population-shifts from bacteria-dominated to fungus-dominated communities. Further analyses by an array of optical microscopic, transcriptional and enzyme-activity techniques yielded correlated results, suggesting that such population shifts occurred along with early removal of hemicellulose followed by attack on the consequently uncovered cellulose as the composting progressed.

Conclusion:

The observed shifts in dominance by representative microbial groups, along with the observed different patterns in the gene expression and enzymatic activities between cellulases, hemicellulases, and ligninases during the composting process, provide new perspectives for biomass-derived biotechnology such as consolidated bioprocessing (CBP) and solid-state fermentation for the production of cellulolytic enzymes and biofuels.Source:

http://www.biotechnologyforbiofuels.com/rss/

Posted in Biotechnology

Comments Off on Tracking dynamics of plant biomass composting by changes in substrate structure, microbial community, and enzyme activity

Two structurally discrete GH7-cellobiohydrolases compete for the same cellulosic substrate fiber

Background:

Cellulose consisting of arrays of linear beta-1,4 linked glucans, is the most abundant carbon-containing polymer present in biomass. Recalcitrance of crystalline cellulose towards enzymatic degradation is widely reported and is the result of intra- and inter-molecular hydrogen bonds within and among the linear glucans. Cellobiohydrolases are enzymes that attack crystalline cellulose. Here we report on two forms of glycosyl hydrolase family 7 cellobiohydrolases common to all Aspergillii that attack Avicel, cotton cellulose and other forms of crystalline cellulose.

Results:

Cellobiohydrolases Cbh1 and CelD have similar catalytic domains but only Cbh1 contains a carbohydrate-binding domain (CBD) that binds to cellulose. Structural superpositioning of Cbh1 and CelD on the Talaromyces emersonii Cel7A 3-dimensional structure, identifies the typical tunnel-like catalytic active site while Cbh1 shows an additional loop that partially obstructs the substrate-fitting channel. CelD does not have a CBD and shows a four amino acid residue deletion on the tunnel-obstructing loop providing a continuous opening in the absence of a CBD. Cbh1 and CelD are catalytically functional and while specific activity against Avicel is 7.7 and 0.5 U.mg prot-1, respectively specific activity on pNPC is virtually identical. Cbh1 is slightly more stable to thermal inactivation compared to CelD and is much less sensitive to glucose inhibition suggesting that an open tunnel configuration, or absence of a CBD, alters the way the catalytic domain interacts with the substrate. Cbh1 and CelD enzyme mixtures on crystalline cellulosic substrates show a strong combinatorial effort response for mixtures where Cbh1 is present in 2:1 or 4:1 molar excess. When CelD was overrepresented the combinatorial effort could only be partially overcome. CelD appears to bind and hydrolyze only loose cellulosic chains while Cbh1 is capable of opening new cellulosic substrate molecules away from the cellulosic fiber.

Conclusion:

Cellobiohydrolases both with and without a CBD occur in most fungal genomes where both enzymes are secreted, and likely participate in cellulose degradation. The fact that only Cbh1 binds to the substrate and in combination with CelD exhibits strong synergy only when Cbh1 is present in excess, suggests that Cbh1 unties enough chains from cellulose fibers, thus enabling processive access of CelD.Source:

http://www.biotechnologyforbiofuels.com/rss/

Posted in Biotechnology

Comments Off on Two structurally discrete GH7-cellobiohydrolases compete for the same cellulosic substrate fiber

Techno-economic evaluation of 2nd generation bioethanol production from sugar cane bagasse and leaves integrated with the sugar-based ethanol process

Background:

Bioethanol produced from the lignocellulosic fractions of sugar cane (bagasse and leaves), i.e. second generation (2G) bioethanol, has a promising market potential as an automotive fuel; however, the process is still under investigation on pilot/demonstration scale. From a process perspective, improvements in plant design can lower the production cost, providing better profitability and competitiveness if the conversion of the whole sugar cane is considered. Simulations have been performed with AspenPlus to investigate how process integration can affect the minimum ethanol selling price of this 2G process (MESP-2G), as well as improve the plant energy efficiency. This is achieved by integrating the well-established sucrose-to-bioethanol process with the enzymatic process for lignocellulosic materials. Bagasse and leaves were steam pretreated using H3PO4 as catalyst and separately hydrolysed and fermented.

Results:

The addition of a steam dryer, doubling of the enzyme dosage in enzymatic hydrolysis, including leaves as raw material in the 2G process, heat integration and the use of more energy-efficient equipment led to a 37 % reduction in MESP-2G compared to the Base case. Modelling showed that the MESP for 2G ethanol was 0.97 US$/L, while in the future it could be reduced to 0.78 US$/L. In this case the overall production cost of 1G + 2G ethanol would be about 0.40 US$/L with an output of 102 L/ton dry sugar cane including 50 % leaves. Sensitivity analysis of the future scenario showed that a 50 % decrease in the cost of enzymes, electricity or leaves would lower the MESP-2G by about 20%, 10% and 4.5%, respectively.

Conclusions:

According to the simulations, the production of 2G bioethanol from sugar cane bagasse and leaves in Brazil is already competitive (without subsidies) with 1G starch-based bioethanol production in Europe. Moreover 2G bioethanol could be produced at a lower cost if subsidies were used to compensate for the opportunity cost from the sale of excess electricity and if the cost of enzymes continues to fall.Source:

http://www.biotechnologyforbiofuels.com/rss/

Posted in Biotechnology

Comments Off on Techno-economic evaluation of 2nd generation bioethanol production from sugar cane bagasse and leaves integrated with the sugar-based ethanol process

Biofuels can lead to more U.S based Biotechnology jobs

America is making efforts for increasing the domestic production of biofuels so that it could lead to the creation of more jobs in this sector. For this purpose President Bush is making whole hearted efforts and is undertaking panel discussions on advancements in industrial biotechnology so that it could aid in increasing the production of ethanol. Jim Greenwood, President and CEO, Biotechnology Industry Organization stated: We appreciate the personal interest that President Bush has taken in boosting domestic biofuels production. The President’s recent statements underline his commitment to developing new biofuels technologies. We believe President Bush’s visit to Novozymes sends the world a strong message about the importance of the work that industrial biotechnology companies are doing to provide a key enabling technology for large-scale production of ethanol This is expected to act as a booster for the U.S based biotechnology jobs as the U.S government is making efforts for reducing the dependence on petroleum based energy fuels and is looking towards industrial biotechnology for offering cheap forms of alternate and renewable sources of energy in the form of biofuels. It is expected that it would lead to the creation of more jobs for the country.

Posted in Biotechnology

Comments Off on Biofuels can lead to more U.S based Biotechnology jobs