-

The Future Of Nano Technology

Categories

- Ai

- Alan Watts

- Anatomy

- Andropause

- Anti-Aging Medicine

- Arthritis

- Artificial General Intelligence

- Artificial Intelligence

- Artificial Super Intelligence

- Ataxia

- Autism

- Biochemistry

- BioEngineering

- Biotechnology

- Bitcoin

- Chemistry

- Cryonics

- Cryptocurrency

- David Sinclair

- Dementia

- Diet Science

- Diseases

- Eczema

- Elon Musk

- Futurism

- Gene Medicine

- Gene Therapy

- Gene therapy

- Genetic Medicine

- Genetic Therapy

- Global News Feed

- Healthy Lifestyle

- Healthy Living

- HGH Physicians

- Hormone Optimization

- Hormone Replacement Therapy

- Hormone Replacement Treatment

- Human Genetic Engineering

- Human Immortality

- Human Longevity

- Human Reproduction

- Hypogonadism

- Hypopituitarism

- Hypothyroidism

- Immortality

- Immortality Medicine

- Inflammation

- Injectable Growth Hormone

- Integrative Medicine

- Life Skills

- Longevity

- Longevity Medicine

- Low T

- Machine Learning

- Mars Colony

- Medical School

- Menopause

- multiple-sclerosis

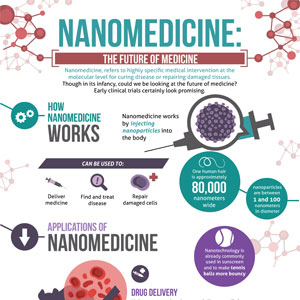

- Nano Medicine

- Nanomedicine

- Nanotechnology

- Neurology

- Parkinson's disease

- Pharmacogenomics

- Protein Folding

- Psoriasis

- Quantum Computing

- Regenerative Medicine

- Resveratrol

- Sermorelin Physicians

- Singularity

- Spacex

- Stem Cell Therapy

- Stem Cells

- Stemcell Therapy

- Testosterone

- Testosterone Physicians

- Transhuman

- Transhumanism

- Transhumanist

- Uncategorized

- Veganism

- Vegetarianism

- Vitamin Research

- Wellness

-

Recent Posts

- Nanoscope Therapeutics: Gene Therapy Improves Visual Acuity in Patients with Retinitis Pigmentosa – 2 Minute Medicine

- College of Engineering Launches New Collaboratory for Biomedical and Bioengineering Innovation – UConn Today – University of Connecticut

- "The best decision I ever made:" Patel earns degree in biological engineering – University of Missouri College of Engineering

- Investigation of inherited noncoding genetic variation impacting the pharmacogenomics of childhood acute … – Nature.com

- Pharmacogenomics could improve medication safety and reduce waste – Healthcare IT News

Archives

Popular Key Word Searches

- centraltph

- bicarbonate and growth immunity ray peat

- vrcc neurology

- bibliotecapleyades/amrita-longevity-immortality

- cbr xmen anatomy

- Medical genetics wikipedia

- immortality medicine

- GrabPay

- Grab Pay Philippines

- GrabPay Vietnam

- GrabPay Philippines

- dr weil psoriasis

- what does recovered mean covid-19

- tony pantalleresco

- tony pantalleresco herbalist book

- herbsplusbeadworks

- herbsplusbeadworks website

- hailie vanderven

- princeton longevity center scam

- aetna genetic testing policy

- anatomy of hell

- biggie

- longevity claims

- augmentinforce tony pantalleresco

- tony pantalleresco website

| Search Immortality Topics: |

Category Archives: Biotechnology

Dylan Koski-Budabin – Biotechnology Presentation – Video

Dylan Koski-Budabin - Biotechnology Presentation

Recombinant DNA to produce human proteins

By: Dylan Koski-Budabin

Read the original post:

Dylan Koski-Budabin - Biotechnology Presentation - Video

Posted in Biotechnology

Comments Off on Dylan Koski-Budabin – Biotechnology Presentation – Video

Functional heterologous expression of an engineered full length CipA from Clostridium thermocellum in Thermoanaerobacterium saccharolyticum

Background:

Cellulose is highly recalcitrant and thus requires a specialized suite of enzymes to solubilize it into fermentable sugars. In C. thermocellum, these extracellular enzymes are present as a highly active multi-component system known as the cellulosome. This study explores the expression of a critical C. thermocellum cellulosomal component in T. saccharolyticum as a step toward creating a thermophilic bacterium capable of consolidated bioprocessing by employing heterologously expressed cellulosomes.

Results:

We developed an inducible promoter system based on the native T. saccharolyticum xynA promoter, which was shown to be induced by xylan and xylose. The promoter was used to express the cellulosomal component cipA*, an engineered form of the wild-type cipA from C. thermocellum. Expression and localization to the supernatant were both verified for CipA*. When a DeltacipA mutant C. thermocellum strain was cultured with a CipA*-expressing T. saccharolyticum strain, hydrolysis and fermentation of 10 grams per liter SigmaCell 101, a highly crystalline cellulose, were observed. This trans-species complementation of a cipA deletion demonstrated the ability for CipA* to assemble a functional cellulosome.

Conclusion:

This study is the first example of an engineered thermophile heterologously expressing a structural component of a cellulosome. To achieve this goal we developed and tested an inducible promoter for controlled expression in T. saccharolyticum as well as a synthetic cipA. In addition, we demonstrate a high degree of hydrolysis (up to 93%) on microcrystalline cellulose.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/32

Posted in Biotechnology

Comments Off on Functional heterologous expression of an engineered full length CipA from Clostridium thermocellum in Thermoanaerobacterium saccharolyticum

ONEIA Presents… Web-I (Waterloo Environmental Biotechnology Inc.) – Video

ONEIA Presents... Web-I (Waterloo Environmental Biotechnology Inc.)

Find out more about how Web-I uses plants to remove pollutants from the soil. Find out more about them at http://www.waterlooenvironmentalbiotechnology.com.

By: ONEIAmedia

Read the original:

ONEIA Presents... Web-I (Waterloo Environmental Biotechnology Inc.) - Video

Posted in Biotechnology

Comments Off on ONEIA Presents… Web-I (Waterloo Environmental Biotechnology Inc.) – Video

Single-step ethanol production from lignocellulose using novel extremely thermophilic bacteria

Background:

Consolidated bioprocessing (CBP) of lignocellulosic biomass to ethanol using thermophilic bacteria provides a promising solution for efficient lignocellulose conversion without the need for additional cellulolytic enzymes. Most studies on the thermophilic CBP concentrate on co-cultivation of the thermophilic cellulolytic bacterium Clostridium thermocellum with non-cellulolytic thermophilic anaerobes at temperatures of 55[degree sign]C-60[degree sign]C.

Results:

We have specifically screened for cellulolytic bacteria growing at temperatures >70[degree sign]C to enable direct conversion of lignocellulosic materials into ethanol. Seven new strains of extremely thermophilic anaerobic cellulolytic bacteria of the genus Caldicellulosiruptor and eight new strains of extremely thermophilic xylanolytic/saccharolytic bacteria of the genus Thermoanaerobacter isolated from environmental samples exhibited fast growth at 72[degree sign]C, extensive lignocellulose degradation and high yield ethanol production on cellulose and pretreated lignocellulosic biomass. Monocultures of Caldicellulosiruptor strains degraded up to 89-97% of the cellulose and hemicellulose polymers in pretreated biomass and produced up to 72 mM ethanol on cellulose without addition of exogenous enzymes. In dual co-cultures of Caldicellulosiruptor strains with Thermoanaerobacter strains the ethanol concentrations rose 2- to 8.2-fold compared to cellulolytic monocultures. A co-culture of Caldicellulosiruptor DIB 087C and Thermoanaerobacter DIB 097X was particularly effective in the conversion of cellulose to ethanol, ethanol comprising 34.8 mol% of the total organic products. In contrast, a co-culture of Caldicellulosiruptor saccharolyticus DSM 8903 and Thermoanaerobacter mathranii subsp. mathranii DSM 11426 produced only low amounts of ethanol.

Conclusions:

The newly discovered Caldicellulosiruptor sp. strain DIB 004C was capable of producing unexpectedly large amounts of ethanol from lignocellulose in fermentors. The established co-cultures of new Caldicellulosiruptor strains with new Thermoanaerobacter strains underline the importance of using specific strain combinations for high ethanol yields. These co-cultures provide an efficient CBP pathway for ethanol production and represent an ideal starting point for development of a highly integrated commercial ethanol production process.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/31

Posted in Biotechnology

Comments Off on Single-step ethanol production from lignocellulose using novel extremely thermophilic bacteria

Carbohydrate-binding modules (CBMs) revisited. reduced amount of water counterbalances the need for CBMs

Background:

A vast number of organisms are known to produce structurally diversified cellulases capable of degrading cellulose, the most abundant biopolymer on earth. The generally accepted paradigm is that the carbohydrate-binding modules (CBMs) of cellulases are required for efficient saccharification of insoluble substrates. Based on sequence data, surprisingly more than 60% of the cellulases identified lack carbohydrate-binding modules or alternative protein structures linked to cellulases (dockerins). This finding poses the question about the role of the CBMs: why would most cellulases lack CBMs, if they are necessary for the efficient hydrolysis of cellulose?

Results:

The advantage of CBMs, which increase the affinity of cellulases to substrates, was found to be diminished by reducing the amount of water in the hydrolytic system, which increases the probability of enzyme-substrate interaction. At low substrate concentration (1% w/w), CBMs were found to be more important in the catalytic performance of the cellobiohydrolases TrCel7A and TrCel6A of Trichoderma reesei as compared to that of the endoglucanases TrCel5A and TrCel7B. Increasing the substrate concentration while maintaining the enzyme-to-substrate ratio enhanced adsorption of TrCel7A, independent of the presence of the CBM. At 20% (w/w) substrate concentration, the hydrolytic performance of cellulases without CBMs caught up with that of cellulases with CBMs. This phenomenon was more noticeable on the lignin-containing pretreated wheat straw as compared to the cellulosic Avicel, presumably due to unproductive adsorption of enzymes to lignin.

Conclusions:

Here we propose that the water content in the natural environments of carbohydrate-degrading organisms might have led to the evolution of various substrate-binding structures. In addition, some well recognized problems of economical saccharification such as unproductive binding of cellulases, which reduces the hydrolysis rate and prevents recycling of enzymes, could be partially overcome by omitting CBMs. This finding could help solve bottlenecks of enzymatic hydrolysis of lignocelluloses and speed up commercialization of second generation bioethanol.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/30

Posted in Biotechnology

Comments Off on Carbohydrate-binding modules (CBMs) revisited. reduced amount of water counterbalances the need for CBMs

High-level expression and characterization of a chimeric lipase from Rhizopus oryzae for biodiesel production

Background:

Production of biodiesel from non-edible oils is receiving increasing attention. Tung oil, called "China wood oil" is one kind of promising non-edible biodiesel oil in China. To our knowledge, tung oil has not been used to produce biodiesel by enzymatic method. The enzymatic production of biodiesel has been investigated extensively by using Rhizopus oryzae lipase as catalyst. However, the high cost of R. oryzae lipase remains a barrier for its industrial applications. Through different heterologous expression strategies and fermentation techniques, the highest expression level of the lipase from R. oryzae reached 1334 U/mL in Pichia pastoris, which is still not optimistic for industry applications.

Results:

The prosequence of lipases from Rhizopus sp. is very important for the folding and secretion of an active lipase. A chimeric lipase from R. oryzae was constructed by replacing the prosequence with that from the R. chinensis lipase and expressed in P. pastoris. The maximum activity of the chimera reached 4050 U/mL, which was 11 fold higher than that of the parent. The properties of the chimera were studied. The immobilized chimera was used successfully for biodiesel production from tung oil, which achieved higher FAME yield compared with the free chimeric lipase, non-chimeric lipase and mature lipase. By response surface methodology, three variables, water content, methanol to tung oil molar ratio and enzyme dosage were proved to be crucial parameters for biosynthesis of FAME and the FAME yield reached 91.9+/-2.5 % at the optimized conditions by adding 5.66 wt.% of the initial water based on oil weight, 3.88 of methanol to tung oil molar ratio and 13.24 wt.% of enzyme concentration based on oil weight at 40 [degree sign]C.

Conclusions:

This is the first report on improving the expression level of the lipase from R. oryzae by replacing prosequences. The immobilized chimera was used successfully for biodiesel production from tung oil. Using tung oil as non-edible raw material and a chimeric lipase from R. oryzae as an economic catalyst make this study a promising one for biodiesel applications.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/29

Posted in Biotechnology

Comments Off on High-level expression and characterization of a chimeric lipase from Rhizopus oryzae for biodiesel production