-

The Future Of Nano Technology

Categories

- Ai

- Alan Watts

- Anatomy

- Andropause

- Anti-Aging Medicine

- Arthritis

- Artificial General Intelligence

- Artificial Intelligence

- Artificial Super Intelligence

- Ataxia

- Autism

- Biochemistry

- BioEngineering

- Biotechnology

- Bitcoin

- Chemistry

- Cryonics

- Cryptocurrency

- David Sinclair

- Dementia

- Diet Science

- Diseases

- Eczema

- Elon Musk

- Futurism

- Gene Medicine

- Gene therapy

- Gene Therapy

- Genetic Medicine

- Genetic Therapy

- Global News Feed

- Healthy Lifestyle

- Healthy Living

- HGH Physicians

- Hormone Optimization

- Hormone Replacement Therapy

- Hormone Replacement Treatment

- Human Genetic Engineering

- Human Immortality

- Human Longevity

- Human Reproduction

- Hypogonadism

- Hypopituitarism

- Hypothyroidism

- Immortality

- Immortality Medicine

- Inflammation

- Injectable Growth Hormone

- Integrative Medicine

- Life Skills

- Longevity

- Longevity Medicine

- Low T

- Machine Learning

- Mars Colony

- Medical School

- Menopause

- multiple-sclerosis

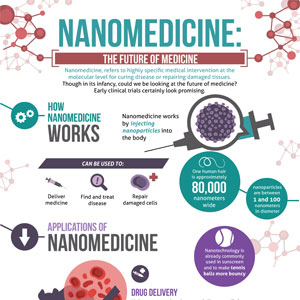

- Nano Medicine

- Nanomedicine

- Nanotechnology

- Neurology

- Parkinson's disease

- Pharmacogenomics

- Protein Folding

- Psoriasis

- Quantum Computing

- Regenerative Medicine

- Resveratrol

- Sermorelin Physicians

- Singularity

- Spacex

- Stem Cell Therapy

- Stem Cells

- Stemcell Therapy

- Testosterone

- Testosterone Physicians

- Transhuman

- Transhumanism

- Transhumanist

- Uncategorized

- Veganism

- Vegetarianism

- Vitamin Research

- Wellness

-

Recent Posts

- Cheap longevity drug? Researchers aim to test if metformin can slow down aging : Shots – Health News – NPR

- The U.S. Needs to ‘Get It Right’ on AI – TIME

- Big Tech keeps spending billions on AI. There’s no end in sight. – The Washington Post

- Racist AI Deepfake of Baltimore Principal Leads to Arrest – The New York Times

- A Baltimore-area teacher is accused of using AI to make his boss appear racist – NPR

Archives

Popular Key Word Searches

- centraltph

- bicarbonate and growth immunity ray peat

- vrcc neurology

- bibliotecapleyades/amrita-longevity-immortality

- cbr xmen anatomy

- Medical genetics wikipedia

- immortality medicine

- GrabPay

- Grab Pay Philippines

- GrabPay Vietnam

- GrabPay Philippines

- dr weil psoriasis

- what does recovered mean covid-19

- tony pantalleresco

- tony pantalleresco herbalist book

- herbsplusbeadworks

- herbsplusbeadworks website

- hailie vanderven

- princeton longevity center scam

- aetna genetic testing policy

- anatomy of hell

- biggie

- longevity claims

- augmentinforce tony pantalleresco

- tony pantalleresco website

| Search Immortality Topics: |

Category Archives: Biotechnology

Novel monosaccharide fermentation products in Caldicellulosiruptor saccharolyticus identified using NMR spectroscopy

Background:

Caldicellulosiruptor saccharolyticus is a thermophilic, Gram-positive, non-spore forming, strictly anaerobic bacterium of interest in potential industrial applications, including the production of biofuels such as hydrogen or ethanol from lignocellulosic biomass through fermentation. High-resolution, solution-state nuclear magnetic resonance (NMR) spectroscopy is a useful method for the identification and quantification of metabolites that result from growth on different substrates. NMR allows facile resolution of isomeric (identical mass) constituents and does not destroy the sample.

Results:

Profiles of metabolites produced by the thermophilic cellulose-degrading bacterium Caldicellulosiruptor saccharolyticus DSM 8903 strain following growth on different monosaccharides (D-glucose, D-mannose, L-arabinose, D-arabinose, D-xylose, L-fucose, and D-fucose) as carbon sources revealed several unexpected fermentation products, suggesting novel metabolic capacities and unexplored metabolic pathways in this organism. Both 1H and 13C nuclear magnetic resonance (NMR) spectroscopy were used to determine intracellular and extracellular metabolite profiles. One dimensional 1H NMR spectral analysis was performed by curve fitting against spectral libraries provided in the Chenomx software; 2-D homonuclear and heteronuclear NMR experiments were conducted to further reduce uncertainties due to unassigned, overlapping, or poorly-resolved peaks. In addition to expected metabolites such as acetate, lactate, glycerol, and ethanol, several novel fermentation products were identified: ethylene glycol (from growth on D-arabinose), acetoin and 2,3-butanediol (from growth on D-glucose, L-arabinose, and D-xylose), and hydroxyacetone (from growth on D-mannose, L-arabinose, and D-xylose). Production of ethylene glycol from D-arabinose was particularly notable, with around 10% of the substrate carbon converted into this uncommon fermentation product.

Conclusions:

The present research shows that C. saccharolyticus, already of substantial interest due to its capability for biological ethanol and hydrogen production, has further metabolic potential for production of higher molecular weight compounds, such as acetoin and 2,3-butanediol, as well as hydroxyacetone and the uncommon fermentation product ethylene glycol. In addition, application of nuclear magnetic resonance (NMR) spectroscopy facilitates identification of novel metabolites, which is instrumental for production of desirable bioproducts from biomass through microbial fermentation.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/47

Posted in Biotechnology

Comments Off on Novel monosaccharide fermentation products in Caldicellulosiruptor saccharolyticus identified using NMR spectroscopy

Genome-scale analyses of butanol tolerance in Saccharomyces cerevisiae reveal an essential role of protein degradation

Background:

n-Butanol and isobutanol produced from biomass-derived sugars are promising renewable transport fuels and solvents. Saccharomyces cerevisiae has been engineered for butanol production, but its high butanol sensitivity poses an upper limit to product titers that can be reached by further pathway engineering. A better understanding of the molecular basis of butanol stress and tolerance of S. cerevisiae is important for achieving improved tolerance.

Results:

By combining a screening of the haploid S. cerevisiae knock-out library, gene overexpression, and genome analysis of evolutionary engineered n-butanol-tolerant strains, we established that protein degradation plays an essential role in tolerance. Strains deleted in genes involved in the ubiquitin-proteasome system and in vacuolar degradation of damaged proteins showed hypersensitivity to n-butanol. Overexpression of YLR224W, encoding the subunit responsible for the recognition of damaged proteins of an ubiquitin ligase complex, resulted in a strain with a higher n-butanol tolerance. Two independently evolved n-butanol-tolerant strains carried different mutations in both RPN4 and RTG1, which encode transcription factors involved in the expression of proteasome and peroxisomal genes, respectively. Introduction of these mutated alleles in the reference strain increased butanol tolerance, confirming their relevance in the higher tolerance phenotype. The evolved strains, in addition to n-butanol, were also more tolerant to 2-butanol, isobutanol and 1-propanol, indicating a common molecular basis for sensitivity and tolerance to C3 and C4 alcohols.

Conclusions:

This study shows that maintenance of protein integrity plays an essential role in butanol tolerance and demonstrates new promising targets to engineer S. cerevisiae for improved tolerance.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/48

Posted in Biotechnology

Comments Off on Genome-scale analyses of butanol tolerance in Saccharomyces cerevisiae reveal an essential role of protein degradation

Mapping the lignin distribution in pretreated sugarcane bagasse by confocal and fluorescence lifetime imaging microscopy

Background:

Delignification pretreatments of biomass and methods to assess their efficacy are crucial for biomass-to-biofuels research and technology. Here, we applied confocal and fluorescence lifetime imaging microscopy (FLIM) using one- and two-photon excitation to map the lignin distribution within bagasse fibers pretreated with acid and alkali. The evaluated spectra and decay times are correlated with previously calculated lignin fractions. We have also investigated the influence of the pretreatment on the lignin distribution in the cell wall by analyzing the changes in the fluorescence characteristics using two-photon excitation. Eucalyptus fibers were also analyzed for comparison.

Results:

Fluorescence spectra and variations of the decay time correlate well with the delignification yield and the lignin distribution. The decay dependences are considered two-exponential, one with a rapid (tau1) and the other with a slow (tau2) decay time. The fastest decay is associated to concentrated lignin in the bagasse and has a low sensitivity to the treatment. The fluorescence decay time became longer with the increase of the alkali concentration used in the treatment, which corresponds to lignin emission in a less concentrated environment. In addition, the two-photon fluorescence spectrum is very sensitive to lignin content and accumulation in the cell wall, broadening with the acid pretreatment and narrowing with the alkali one. Heterogeneity of the pretreated cell wall was observed.

Conclusions:

Our results reveal lignin domains with different concentration levels. The acid pretreatment caused a disorder in the arrangement of lignin and its accumulation in the external border of the cell wall. The alkali pretreatment efficiently removed lignin from the middle of the bagasse fibers, but was less effective in its removal from their surfaces. Our results evidenced a strong correlation between the decay times of the lignin fluorescence and its distribution within the cell wall. A new variety of lignin fluorescence states were accessed by two-photon excitation, which allowed an even broader, but complementary, optical characterization of lignocellulosic materials. These results suggest that the lignin arrangement in untreated bagasse fiber is based on a well-organized nanoenvironment that favors a very low level of interaction between the molecules.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/43

Posted in Biotechnology

Comments Off on Mapping the lignin distribution in pretreated sugarcane bagasse by confocal and fluorescence lifetime imaging microscopy

Dynamic metabolic modeling of a microaerobic yeast co-culture: predicting and optimizing ethanol production from glucose/xylose mixtures

Background:

A key step in any process that converts lignocellulose to biofuels is the efficient fermentation of both hexose and pentose sugars. The co-culture of respiratory-deficient Saccharomyces cerevisiae and wild-type Scheffersomyces stipitis has been identified as a promising system for microaerobic ethanol production because S. cerevisiae only consumes glucose while S. stipitis efficiently converts xylose to ethanol.

Results:

To better predict how these two yeasts behave in batch co-culture and to optimize system performance, a dynamic flux balance model describing co-culture metabolism was developed from genome-scale metabolic reconstructions of the individual organisms. First a dynamic model was developed for each organism by estimating substrate uptake kinetic parameters from batch pure culture data and evaluating model extensibility to different microaerobic growth conditions. The co-culture model was constructed by combining the two individual models assuming a cellular objective of total growth rate maximization. To obtain accurate predictions of batch co-culture data collected at different microaerobic conditions, the S. cerevisiae maximum glucose uptake rate was reduced from its pure culture value to account for more efficient S. stipitis glucose uptake in co-culture. The dynamic co-culture model was used to predict the inoculum concentration and aeration level that maximized batch ethanol productivity. The model predictions were validated with batch co-culture experiments performed at the optimal conditions. Furthermore, the dynamic model was used to predict how engineered improvements to the S. stipitis xylose transport system could improve co-culture ethanol production.

Conclusions:

These results demonstrate the utility of the dynamic co-culture metabolic model for guiding process and metabolic engineering efforts aimed at increasing microaerobic ethanol production from glucose/xylose mixtures.Source:

http://www.biotechnologyforbiofuels.com/content/6/1/44

Posted in Biotechnology

Comments Off on Dynamic metabolic modeling of a microaerobic yeast co-culture: predicting and optimizing ethanol production from glucose/xylose mixtures

The Mystery about Cyanide Taste

What is potassium cyanide??

A chemical compound with the chemical formula KCN is commonly known as the Potassium cyanide. This is a colorless crystalline compound, highly soluble in water and is similar in appearance as that of sugar. Potassium cyanide is considered to be highly toxic in nature. Potassium cyanide is considered to be one of the most deadly compounds being discovered till date.

Production of Potassium Cyanide:

Potassium Cyanide can be produced mainly by treating hydrogen cyanide in the presence of a fifty percent of an aqueous solution of potassium hydroxide. After that the aqueous solution is either evaporated in a vacuum or by treating the form amide in the presence of potassium hydroxide. On an average per year approximately fifty thousand tons of potassium cyanide are being produced all over the world.

Use of Potassium Cyanide:

Potassium Cyanide is mainly used for the purpose of electroplating, organic synthesis of a number of chemical compounds, gold mining and so on. In accordance with the large scale use of Potassium Cyanide, it is also used in smaller scale applications like in the jewelry manufacturing industry for chemical buffing and gliding. Other than those mentioned earlier, Potassium Cyanide is also used by the entomologists as it is an excellent killing agent, and it has the unique capability of causing minimum damage to the highly fragile specimens.

Mystery about Potassium Cyanide:

Since, the time of its invention, the biggest mystery that has been surrounded with Potassium Cyanide, is about the taste of it. Due to the fact that Potassium Cyanide is exceedingly poisonous substance and can cause death of a person in seconds, the taste of it has remained a mystery or a fact yet to be known to the world. Though, many researches and tests have been conducted to find the taste of Potassium Cyanide but none of them could come up with the appropriate result.

Different views about the taste of Potassium Cyanide:

There has been number of views among the scientists about the taste of the Potassium Cyanide, some of them are as follows:

· Since on hydrolysis of KCN, the resultant compound that are formed are KOH and HCN, which are strong base and weak base respectively, Potassium Cyanide is confirmed to be basic nature. Since at room temperature HCN is a gas which evolves and the solution is expected to have more KOH, so the taste of Potassium Cyanide is assumed to be bitter.

· Some, scientists who have died while finding the taste of Potassium cyanide, could only write the alphabet “S” before dying, so it is not conclusive whether it is sour, sweet or salty in taste.

Conclusion:

Though, a huge number of scientists sacrificed their lives in order to find the taste of Potassium cyanide, but it remained a mystery for long, until and unless a goldsmith from India named MP Prasad in an attempt to commit suicide with the help of Potassium cyanide could finally reveal the taste of Potassium cyanide. As per the suicide note of him the taste of Potassium Cyanide is very much acrid, that is irritatingly harsh and sharp. This fact about the taste of Potassium cyanide is approved by the World Health Organization and is marked as an extraordinary discovery in the field of science.

Source:

http://www.biotechblog.org/entry/mystery-cyanide-taste/

Posted in Biotechnology

Comments Off on The Mystery about Cyanide Taste

Dr.Anju.T.R,Young scient award winner(Dpt. of Biotechnology/centre for neuroscience ,CUSAT) – Video

Dr.Anju.T.R,Young scient award winner(Dpt. of Biotechnology/centre for neuroscience ,CUSAT)

Neonatal hypoxia a major cause of permanent neurological disabilities sustained during childhood has devastating consequences like cognitive dysfunctions, ne...

By: Ajayan Mannoor supran

Read more from the original source:

Dr.Anju.T.R,Young scient award winner(Dpt. of Biotechnology/centre for neuroscience ,CUSAT) - Video

Posted in Biotechnology

Comments Off on Dr.Anju.T.R,Young scient award winner(Dpt. of Biotechnology/centre for neuroscience ,CUSAT) – Video